CIRCULAR GRINDING MACHINES

Designed for external and internal grinding of cylindrical, conical and end surfaces in the chuck and centers.

Designed for external and internal grinding of cylindrical, conical and end surfaces in the chuck and centers.

Designed for external grinding with abrasive or cbn circles of external diameters and adjacent ends, as well as grinding internal holes, cylindrical, conical and end surfaces on parts such as shaft, bushing, axis, flange, cover, etc.

Designed for external and internal grinding of cylindrical, conical and end surfaces in the chuck and centers.

Universal cylindrical grinding machine model OSH-535F2 is designed for grinding the outer cylindrical and conical surfaces with grinding ends, parts inner cylindrical surfaces made of various materials (cast iron, steel and their alloys).

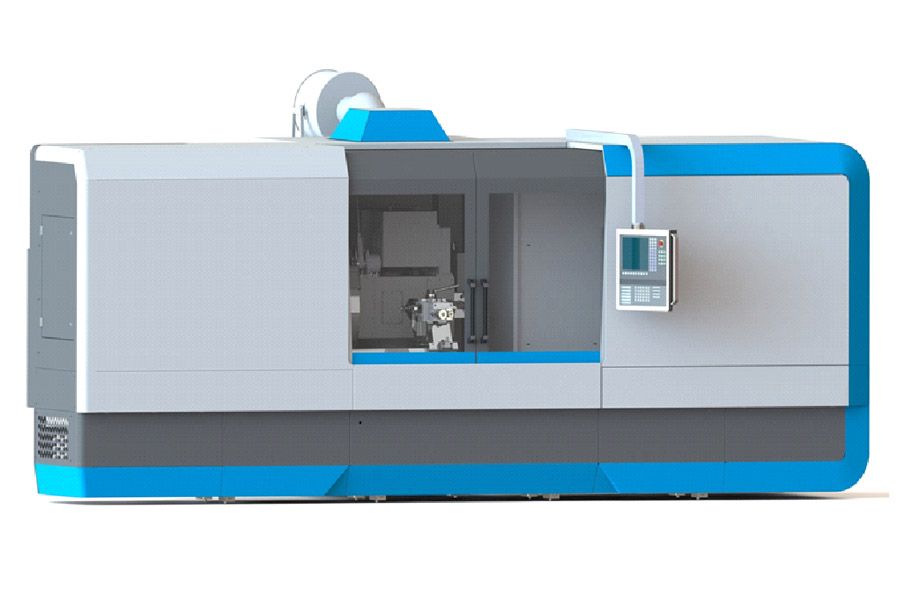

The machine is designed for grinding external and internal cylindrical and conical surfaces, as well as profile grinding of Internal and external surfaces.

The machine is designed for external and internal grinding of cylindrical and conical surfaces with end faces of rotation bodies made of tool steels with stepped and curved profiles.

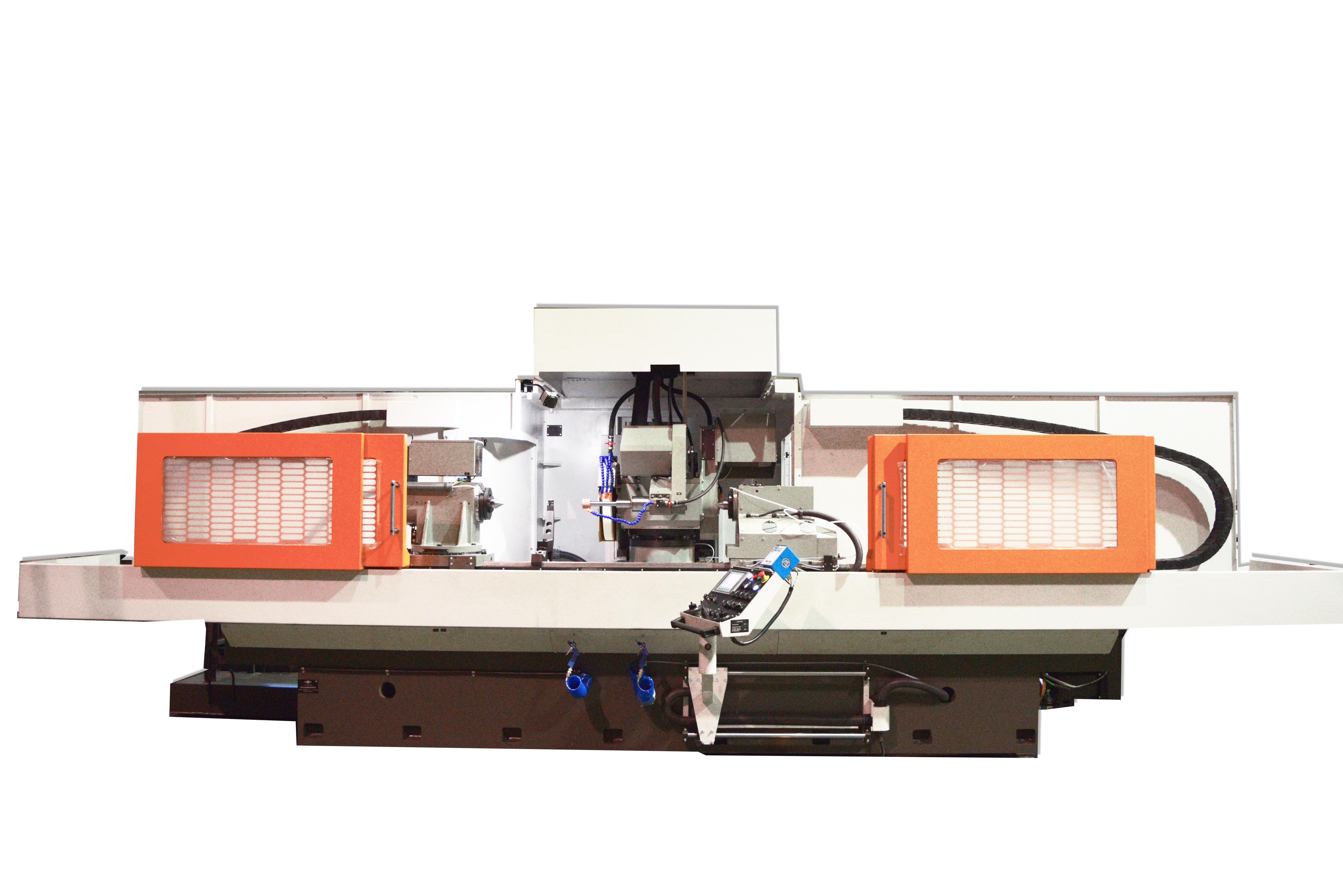

Universal circular grinding machine model OSH-661AF2 is designed for external grinding of smooth cylindrical and conical surfaces with the possibility of internal grinding of holes for finishing spindles.

External surfaces are ground in succession with two grinding wheels (rough and finish grinding).

Designed for external grinding with abrasive or cbn circles of external diameters and adjacent ends, as well as grinding internal holes, cylindrical, conical and end surfaces on parts such as shaft, bushing, axis, flange, cover, etc.

Semiautomatic circular grinding universal machine with CNC model OSH-525F3 version 01 is designed for external and internal grinding of smooth and noncontinuous cylindrical and conic surfaces in bodies of revolution (parts type of shafts, ases, rods, arbours, flanges etc.), fastened in centres or chuck.