- Index

- Catalog

- CIRCULAR GRINDING MACHINES

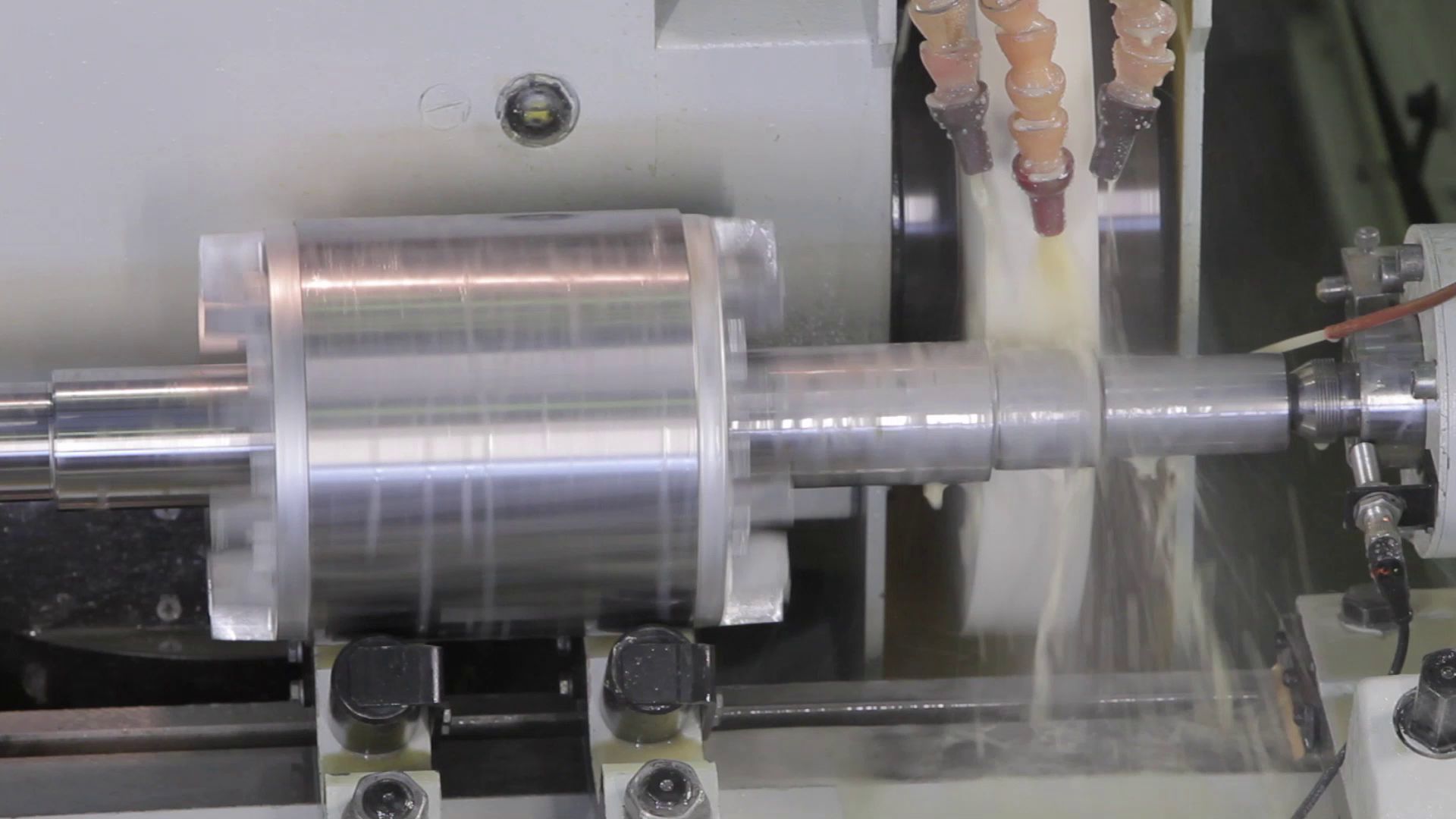

- SEMIAUTOMATIC CIRCULAR GRINDING UNIVERSAL MACHINE WITH CNC OSH-525F3 version 01

SEMIAUTOMATIC CIRCULAR GRINDING UNIVERSAL MACHINE WITH CNC OSH-525F3 version 01

DESCRIPTION

Semiautomatic circular grinding universal machine with CNC model OSH-525F3 version 01 is designed for external and internal grinding of smooth and noncontinuous cylindrical and conic surfaces in bodies of revolution (parts type of shafts, ases, rods, arbours, flanges etc.), fastened in centres or chuck.

Field of machine use is the enterprises of serial and large-scale manufacture. Machine can be equipped with CNC system of the firm “Siemens” or “Mitsubishi” and incremental transducers (linear travel converters) over two programmable coordinates (cross travel of wheel head – coordinate Х, longitudinal travel of table – coordinate Z).

Kinematic diagram of machine must provide the following motions:

- rotation of grinding wheel for external grinding (coordinate SP1);

- rotation of grinding wheel for internal grinding (coordinate SP2);

- cross travel of wheel head (coordinate Х);

- longitudinal travel of table (coordinate Z);

- rotation of machined part (coordinate SP3).

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Maximum diameter / length of installed work piece in centres

220/720 mm

-

Maximum diameter / length of installed work piece in chuck

200/250 mm

-

External diameter/height/internal diameter

500/50/230 mm

-

Main motion drive power

5,5 kW

-

Part rotation frequency

-

-

Discreteness of travel over controllable coordinate Z – longitudinal travel of table

1mkm

-

Discreteness of travel over controllable coordinate Х – cross travel of wheel head

1mkm

-

Dimensions for inward grinding of grinding wheel

-

-

Maximum turning angle of upper table clockwise/anticlockwise

6x6 degrees

-

Maximum turning angle of workhead when machining in chuck clockwise/anticlockwise

30x90 degrees

-

Maximum turning angle of wheel-head clockwise

180 degrees

-

Electric spindle for inward machining power

-

-

Overall dimensions (length x width x height)

3800 x 3850 x 1900 mm

-

Mass

4320 kg

Machine has arrangement with traveling table on which machined part is installed and travel of wheel head perpendicularly to machined part centres axis. Work head with electric drive and tailstock are fastened on working surface of upper table. Wheel head travels are realized over linear roller guide ways by ball-screw pair.

Hydraulic equipment is fulfilled as a separate unit and installed to the right from machine and cooling system is from behind.

Electric cabinet is located to the right from behind of the machine, and to the right in front of machine there is a control panel with CNC system on bracket.

Surfaces machining and grinding wheel dressing is produced in automatic mode as per controlling program (CP), installation and removal of part is realized manually.

Wheel head has an internal grinding spindle and can turn by 180° in horizontal plane manually.

Grinding wheel periphery dressing is realized by dresser diamond. Working zone of grinding is guarded by protective enclosure with open top, front wall has a movable opening door with plexiglass. When grinding coolant-lubricant on water base is used, coolant treatment is realized by magnetic separator and filter-conveyor with filter cloth.

Basing of machined parts is produced in centres of headstock and tailstock or in a chuck, axial orientation of part is produced by means of Renishaw probe by table stroke.

Parts grinding is produced at the expense of machined part rotation and travel of wheel head towards centres axis. Machine has a manual, adjustment and automatic modes of operation.

- machine assembled (with wheel head, headstock and tailstock);

- coolant feed and treatment system;

- hydraulic station;

- electric cabinet;

- control panel with CNC system;

- set of spare parts and attachments, quick wearing parts for guaranty period (12 months) of operation;

- grinding wheel flanges assembled – 2 sets (1 set is installed on machine);

- arbour for static balancing of abrasive wheel assembled with faceplate;

- attachment for static grinding wheel balancing;

- abrasive wheels - 2 pcs. (750 x 305 x 100) mm;

- jaw chuck;

- set of operational –technical documentation in 1 copy;

- universal program of machining.

Equipping the wheel head with device of grinding wheel dynamic balancing. This option includes balancing head of flange type with contactless transmitting apparatus, vibration sensor and electronic device. Use of this device allows to produce automatic balancing of rotating grinding wheel on machine with minimum imbalance.

Equipping with inprocess gage. Inprocess gage of cylindrical diameters of machined parts includes bracket with two measuring heads with function of orientation and measuring contacts and also an electronic device with control panel. Electronic device is fastened on the machine control panel. Use of inprocess gage allows to provide stable getting of machined diameter dimension within ± 0,0025 mm.

Equipping with exhaust. When equipping the machine with cabinet enclosure of working zone it is possible to use the device of sucking off aerosol forming in the process of grinding. This device is a welded base on which welded cylinder with cone, motor with impeller, filtering element, covers with branch pipes and a hose. Exhaust can work autonomously both in manual and in automatic modes and allows to realize the removal of aerosol vapors from the machining zone.

Cabinet enclosure of working zone. Enclosure with closed top, front wall of protection has a movable opening door with plexiglass.

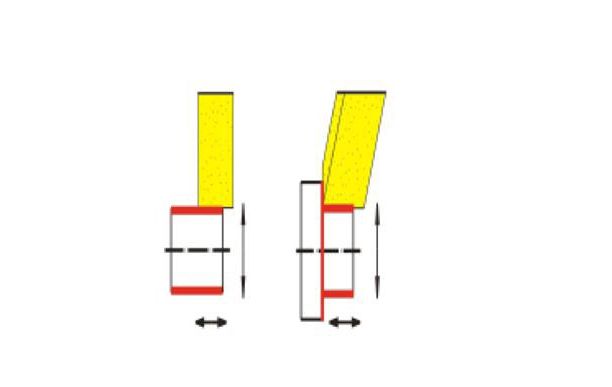

- Equipping with open or closed rest.