- Index

- Catalog

- THREAD GRINDING MACHINES WITH CNC

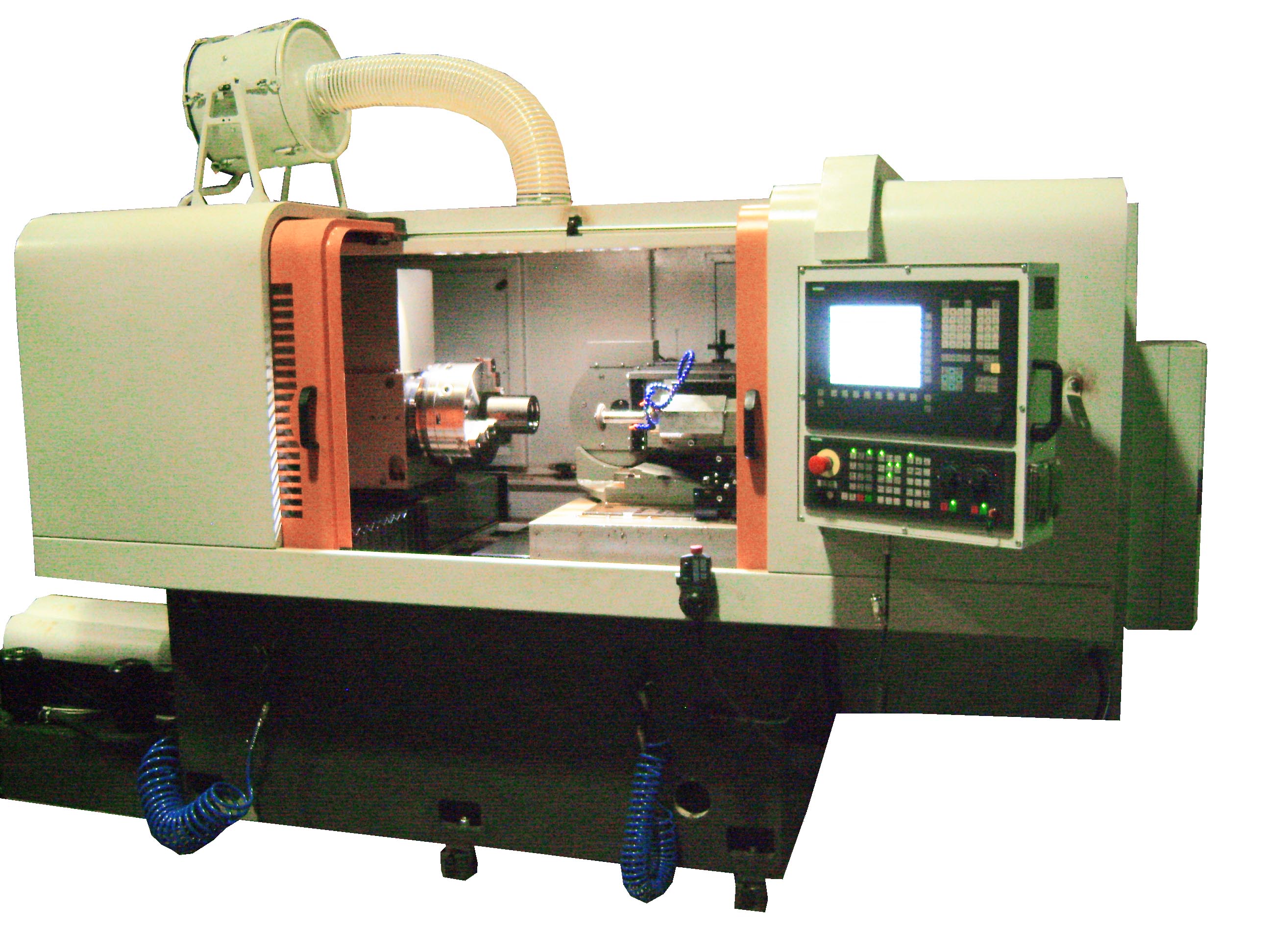

- INTERNAL THREAD GRINDING MACHINE WITH CNC OSH-635.1.FЗ

INTERNAL THREAD GRINDING MACHINE WITH CNC OSH-635.1.FЗ

DESCRIPTION

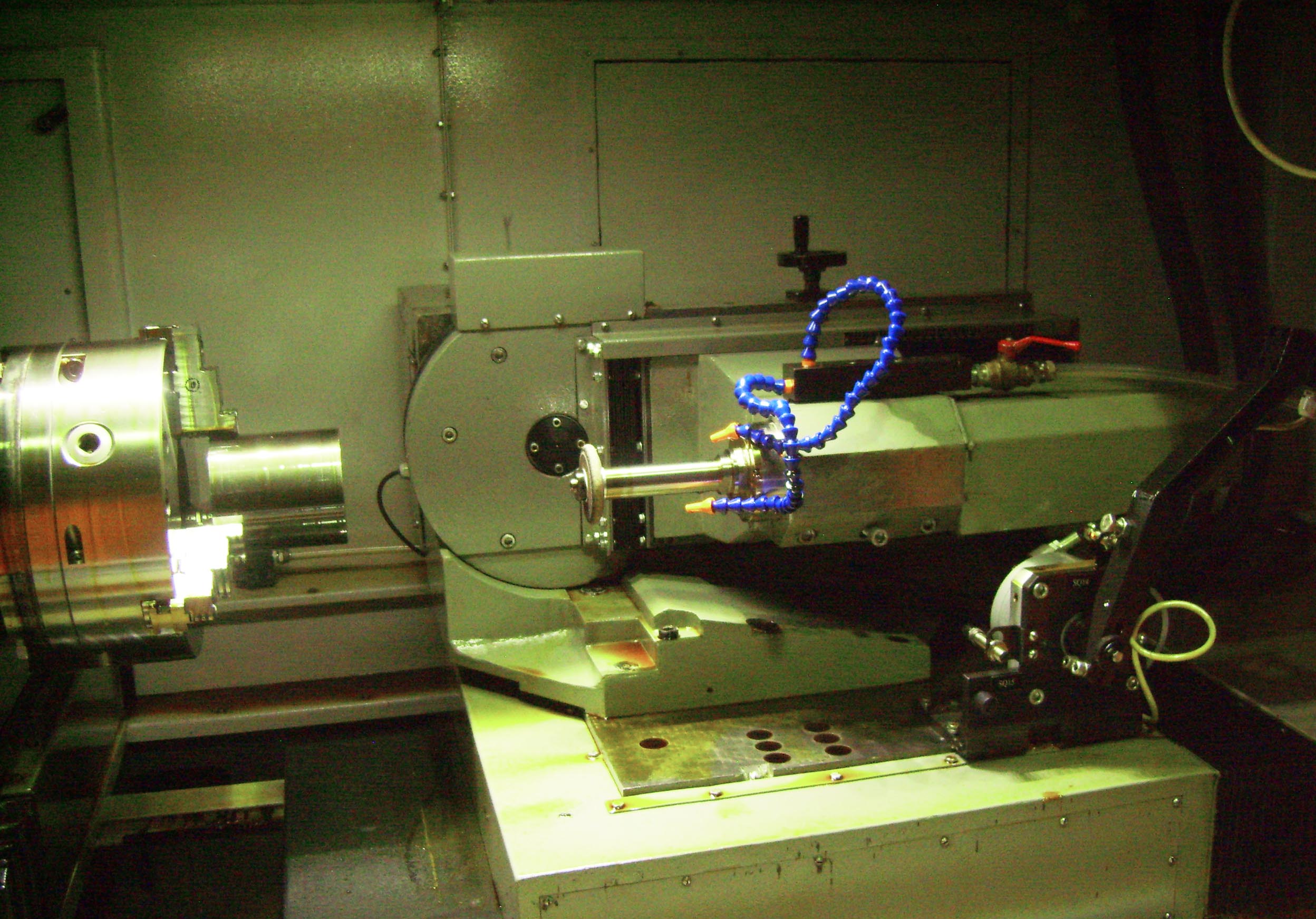

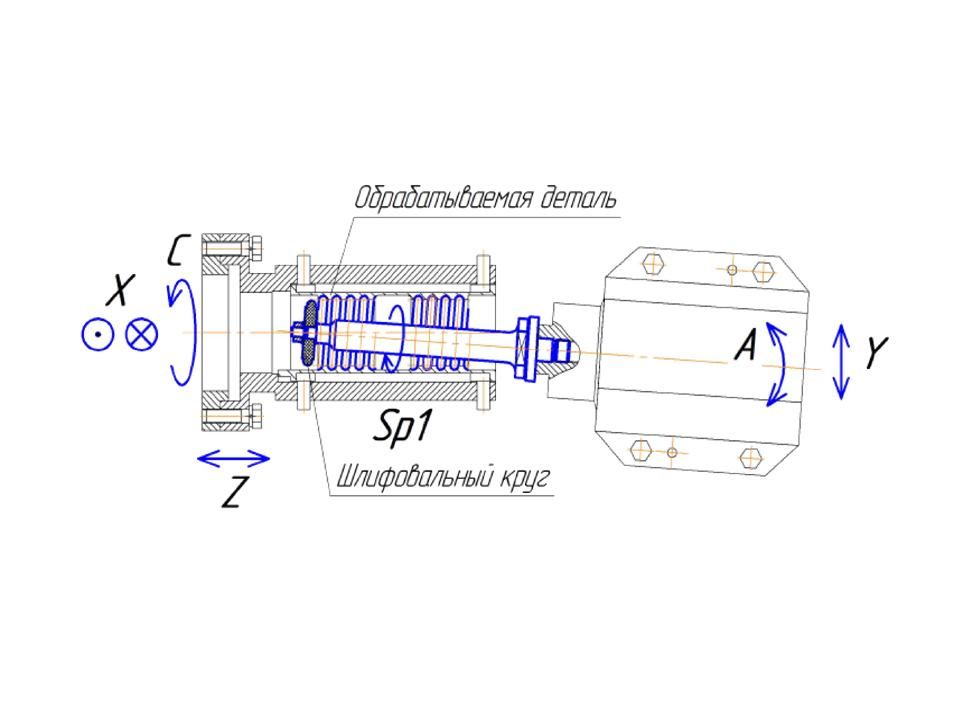

Internal thread grinding machine with CNC model OSH-635FЗ is designed for grinding the internal thread of nuts and ball-screw pair beckets and has the traveling in cross direction slides (coordinate X) and in longitudinal direction table with work head (coordinate Z), wheel head is rotary, travels vertically (coordinate Y). The machine is equipped with CNC system, electric spindle, touch sensor for detection of part location on machine, diamond roller for grinding wheel profile dressing.

DESIGN ADVANTAGES

- CNC system Sinumerik 840Dsl with servo drives Sinamics 120.

- Linear and circular feedback sensors of the firm «Fagor» over programmable coordinates - cross travel of wheel head – coordinate Х; - longitudinal travel of slides with wheel head – coordinate Z; - angular turn of wheel head in vertical plane (tilt angle of thread) – coordinate А; - machined part rotation - coordinate C.

- Electric cabinet of own production with refrigerating unit of the firm «Rittal».

- High precision gapless ball-screw transmissions for: longitudinal travel of slides, cross travel of wheel head.

- Renishaw probe of the firm «Renishаw».

- Enclosure of working zone of «cabinet» type.

- Frequency adjustment of wheel head spindle resolutions.

- Proximity sensors and limit switches of the firm «Balluff».

- Closed roller linear guide ways.

- High precision angular ball bearings for work head spindle and wheel head rotary axis.

- Mechanism of contour dressing by diamond roller from headstock.

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Length of machined workpiece

300 mm

-

Diameter of machined workpiece

330 mm

-

Machined work piece diameter

300 mm

-

Grinding wheel diameter

22...100 mm

-

Grinding wheel height

20 mm

-

Controllable number of coordinates

5

-

Part rotation frequency

1...100 rpm

-

Maximum mass of installed work piece (together with mass of fixing elements)

200 kg

-

Ground thread diameter

25...255 mm

-

Grinding wheel rotation frequency

6000...45000rpm

-

Wheel head angle of turn

-15;+15 degrees

-

Overall dimensions (length x width x height)

3500 x 4100 x 2550 mm

-

Mass

9000 kg

Internal thread grinding machine with CNC model OSH-635FЗ is designed for grinding the internal thread of nuts and ball-screw pair beckets and has the traveling in cross direction slides (coordinate X) and in longitudinal direction table with work head (coordinate Z), wheel head is rotary, travels vertically (coordinate Y). The machine is equipped with CNC system, electric spindle, touch sensor for detection of part location on machine, diamond roller for grinding wheel profile dressing.

- machine assembled with heads and Renishaw probe;

- grinding wheel dressing mechanism;

- hydraulic station;

- system of coolant feed and treatment;

- refrigerating unit of coolant heat setting;

- unit of aerosol exhausting;

- electric cabinet;

- control panel with CNC system;

- set of spare parts and attachments for guarantee period of operation;

- set of operational – technical documentation in English.

Device of machined parts blow-off. This option includes a special gun with polyvinyl pipe through which air is supplied under pressure from extranet. Air supply is realized onto the block installed on the machine bed and further on onto the gun located on the front surface of the bed in the zone of operator’s location. The operator can make blow-off of removed from the table or electromagnetic chuck machined parts with compressed air by pressing the lever of the gun.

Unit for coolant feed and its treatment.

Plant for aerosol exhausting from machining zone.