- Index

- Catalog

- MACHINES FOR CREEP FEED GRINDING OF HARD-TO-MACHINE MATERIALS

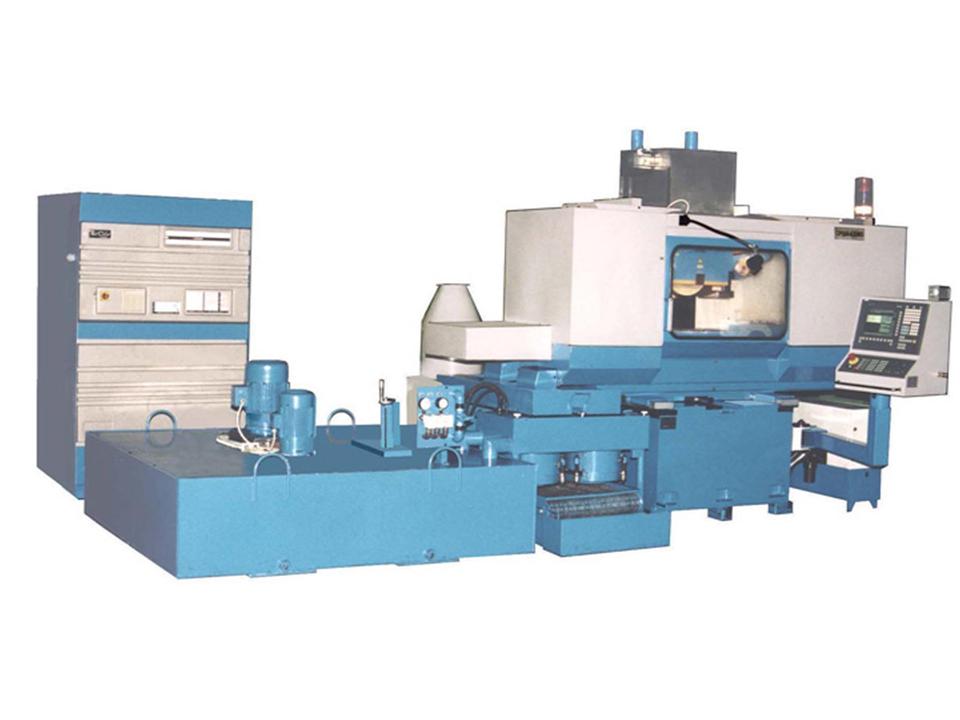

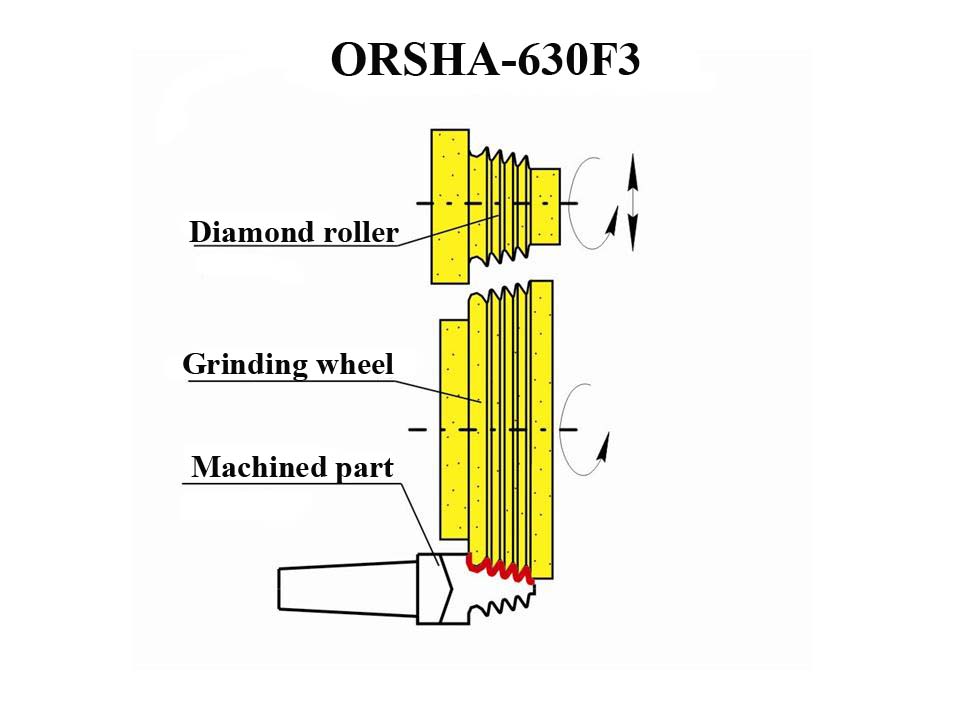

- SEMI-AUTOMATIC MACHINE OF CREEP FEED SURFACE PROFILE GRINDING WITH CNC ORSHA-630F3

SEMI-AUTOMATIC MACHINE OF CREEP FEED SURFACE PROFILE GRINDING WITH CNC ORSHA-630F3

DESCRIPTION

Semi-automatic Orsha-630F3 is designed for high-performance and high-precision abrasive processing of flat surfaces (spikes, grooves) by the method of deep grinding of various products from hard-to-work and heat-resistant materials. Due to the CNC system, it is possible to process difficult-to-profile surfaces.

DESIGN ADVANTAGES

- CNC system SINUMERIK 840DSL of the firm SIEMENS.

- Presence of contour and continuous dressing (in the process of grinding) mechanisms.

- Highly effective system of coolant lubricant feed with stabilization of temperature mode.

- Hydraulic clearing of grinding wheel.

- Effective clearing of lubricant coolant with automatic unloading and removal of sediment.

- Rapid grinding.

- Components of leading world producers: drives SINAMICS of SIEMENS; frequency converters of MITSUBISHI; linear converters of FAGOR; linear guide ways of SCHNEEBERGER; wheel head spindle bearings of FAG, IBC.

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Maximum dimensions of installed workpiece (L x B x H)

630 x 320 x 300 mm

-

Table mirror width

320 mm

-

Table mirror length

630 mm

-

Compound slide maximum travels

370 mm

-

Table maximum travels

750 mm

-

Maximum mass of installed work piece (together with attachment and electromagnetic chuck)

500 kg

-

Maximum distance between table mirror and spindle axis

500 mm

-

Grinding wheel diameter

400 mm

-

Grinding wheel height

20...100 mm

-

Grinding wheel bore diameter

127 mm

-

Main drive power

20 kw

-

Overall dimensions (length x width x height)

5300 x 4120 x 2900 mm

-

Mass

7500 kg