- Index

- Catalog

- MACHINES FOR CREEP FEED GRINDING OF HARD-TO-MACHINE MATERIALS

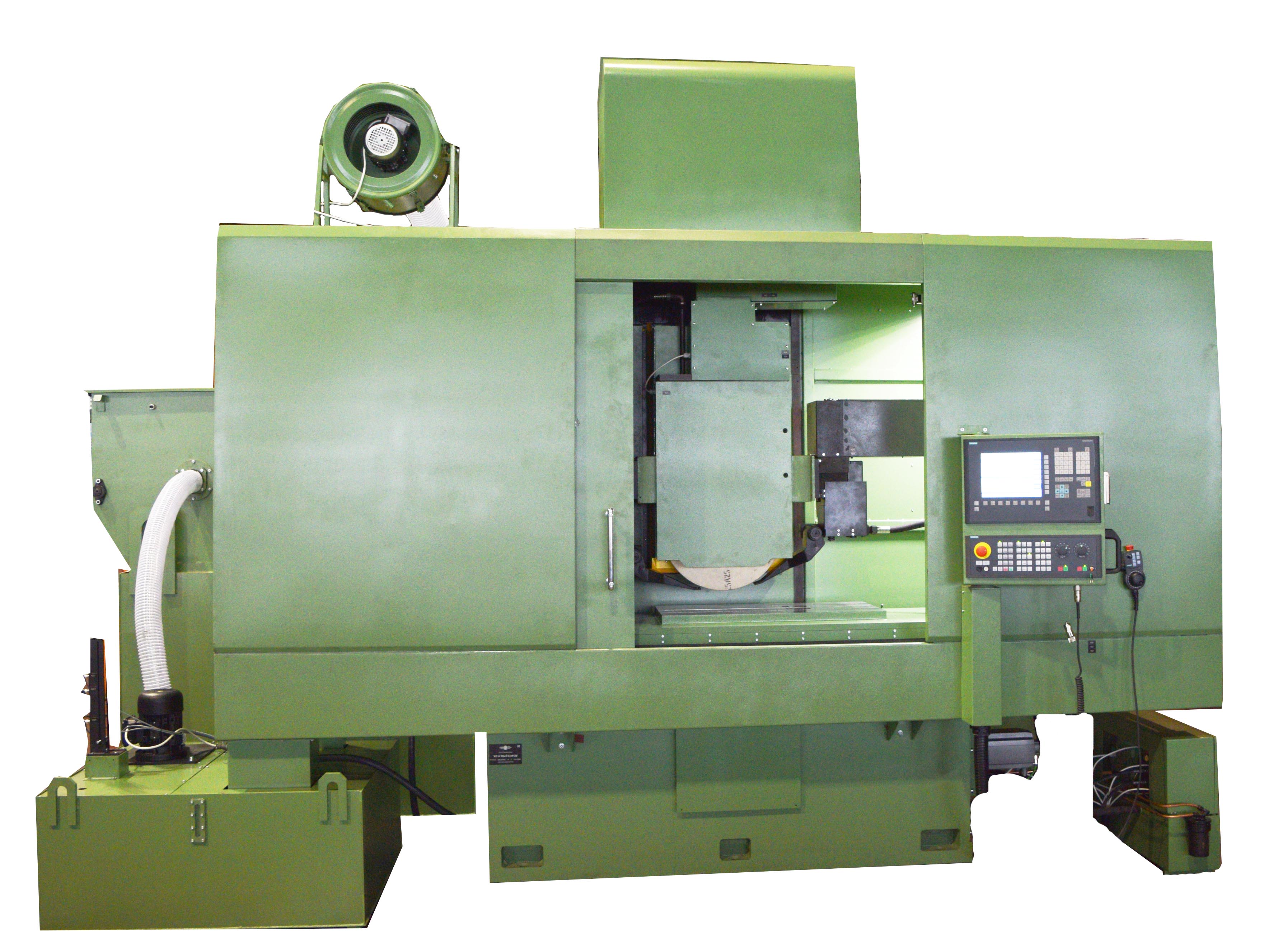

- SEMIAUTOMATIC CREEP FEED SURFACE PROFILE GRINDING MACHINE WITH CNC OSH-221F3

SEMIAUTOMATIC CREEP FEED SURFACE PROFILE GRINDING MACHINE WITH CNC OSH-221F3

DESCRIPTION

Semiautomatic creep feed surface-profile grinding machine with CNC model OSH-221F3 is designed for creep feed grinding of profile surfaces and deep slots of parts made of heat-resistant and other hard-to machine materials by abrasive grinding wheels. Machine has eight programmable coordinates.

Number of controlled coordinates and axes

X-longitudinal table travel

Y-vertical wheel head travel

Z-cross column travel

V-vertical travel of slider dressing mechanism

Q1,Q2- vertical coolant lubricant nozzle ( right,left)

Sp1- grinding wheel rotation frequency

Sp2- diamond roller dressing mechanism rotation frequency

Machine field of use – enterprises of serial and large-scale manufacture.

DESIGN ADVANTAGES

- CNC system «Sinumerik-840Dsl» with Sinamiks drives of the firm Siemens.

- Software for creating parts deep processing with grinding wheel continuous dressing usage programs is installed on the machine.

- Linear displacement photo-discrete converter of firm «Fagor» over coordinates Y,Z, and V.

- Relay ladder logic system electrical cabinet and machine control panel with CNC system.

- Mechanism of grinding wheel continuous dressing by diamond roller.

- Coolant supply and cleaning system.

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Maximum dimensions of installed workpiece (L x B x H)

800 x 400 x 500mm

-

Grinding wheel diameter

500 mm

-

Grinding wheel height

10...100 mm

-

Grinding wheel bore diameter

203 mm

-

Main drive power

28 kW

-

Grinding spindle rotation frequency

(infinite variation)800...2000 rpm

-

Maximum diameter of grinding spindle cone

80 mm

-

Overall dimensions (length x width x height)

5000 x 5000 x 3230mm

-

Mass

12000 kg

Machine has the arrangement with traveling in longitudinal direction table and movable column traveling in cross direction bearing the wheel head.

Longitudinal table provides longitudinal feed when grinding, wheel head travels inside the column vertically.

Grinding wheel continuous dressing mechanism with rotary profile diamond roller is installed on top of wheel head. Coolant lubricant supply nozzles automatic travel mechanisms are installed on housing as the grinding wheel wears. Grinding wheel hydrodynamic cleaning nozzle is mounted on diamond roller continuous dressing mechanism of spindle carriage and it is travel with it.

Machine control is realized by CNC system from machine control panel located in front right of working zone. Working zone of grinding is guarded by protection of cabinet type in which it is foreseen to connect the exhaust system of pumping out coolant-lubricant aerosols. The front wall of protection has the movable opening door with plexiglass.

Profile surfaces grinding and also grinding wheel continuous dressing with automatic wear compensation is produced as per CNC control program (CP) in automatic cycle, at this the in-depth method of grinding is used.

Longitudinal table travel guides lubrication is automatic from host system.

Vertical and cross travel guides lubrication is consistent grease.

Lubrication of all ball screw pairs is consistent grease.

Spindles bearings lubrication is consistent grease for the entire service life.

machine assembly;

- coolant supply and cleaning system with refrigeration unit;

- hydraulic unit;

- electrical cabinet;

- control panel with CNC system;

- aerosol suction unit;

- a set of spare parts and accessories, fast wear parts for 1 year of operation;

- set of mounting supports (shoes) for machine installation-9 PCs .