FORGE-PRESS EQUIPMENT

Open-side crank presses inclinable Orsha-800. Press are designed for cold stamping operations in press forging and can function separately as well as a part of flexible technological system.

Open-side crank presses non-inclinable Orsha-800-40. Press are designed for cold stamping operations in press forging and can function separately as well as a part of flexible technological system.

Open-side crank presses non-inclinable Orsha-1400. Press are designed for cold stamping operations in press forging and can function separately as well as a part of flexible technological system.

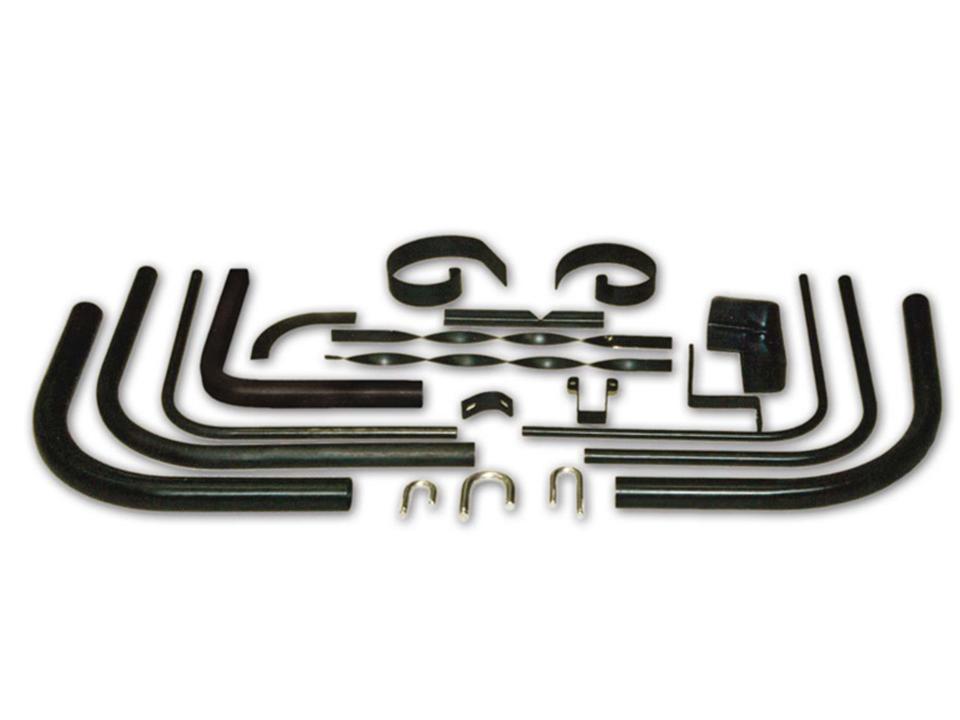

Hydraulic bending machine model MG-120.

Multi-purpose bending machine is intended for bending of pipes, square, profiles, strips, bars, angles, cutting-off of strips, rods, pipes, broaches, twisting, dies, blanks made of different materials with force up to 120 kN (12 t) in metal working.

HYDRAULIC MANUAL PRESS PGR-10

Designed for fulfillment of any repair – assembly operations:

• piercing / pressing-out of bearings, bolts, bushings, etc.

• dressing of carriers, shafts, axes and profiles

• pressing and crushing

• check of weld seam reliability

• tools dressing

• materials strength control

HYDRAULIC MANUAL PRESS PGR-16

Designed for fulfillment of any repair – assembly operations:

• piercing / pressing-out of bearings, bolts, bushings, etc.

• dressing of carriers, shafts, axes and profiles

• pressing and crushing

• check of weld seam reliability

• tools dressing

• materials strength control