- Index

- Catalog

- CIRCULAR GRINDING MACHINES, FACE CIRCULAR GRINDING MACHINES

- CIRCULAR GRINDING SEMIAUTOMATIC MACHINE WITH CNC OSH-660F3 version 15

CIRCULAR GRINDING SEMIAUTOMATIC MACHINE WITH CNC OSH-660F3 version 15

DESCRIPTION

Circular grinding semiautomatic machine with CNC model OSH-660F3 version 15 is designed for external grinding of smooth and discrete cylindrical and conical surfaces in bodies of rotation (parts such as shafts, axis, rods, mandrels, etc.).

The scope of machine use is serial and large-scale production enterprises.

The machine can be equipped with a Siemens, Mitsubishi or Fanuc CNC system and incremental sensors (linear displacement transducers) along two programmable coordinates (wheel-head transverse travel - X coordinate, longitudinal table travel - Z coordinate).

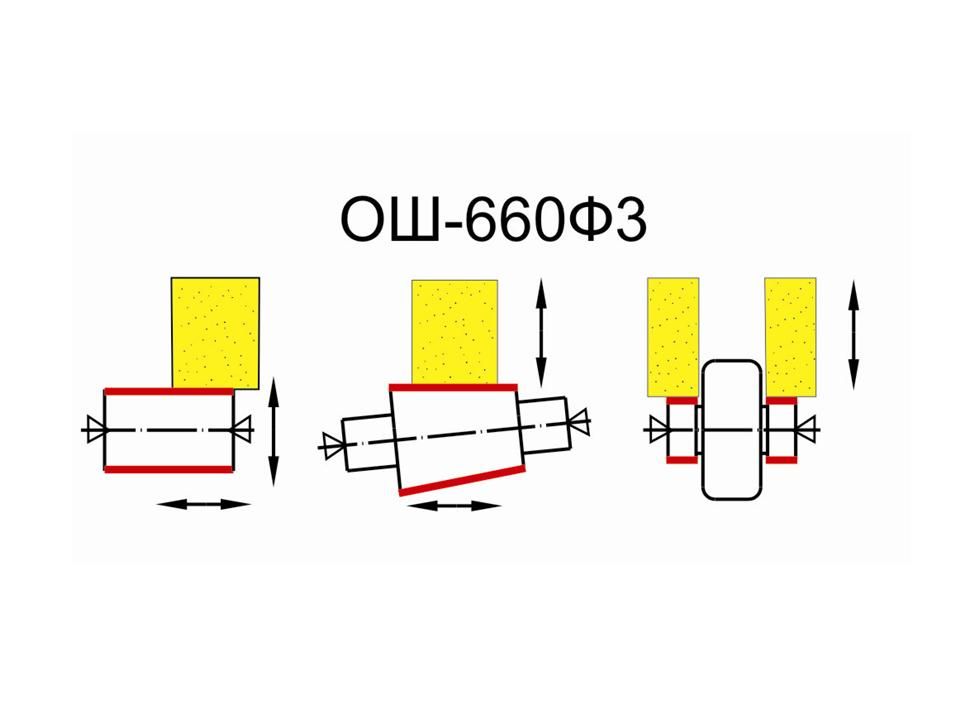

The kinematic diagram of the machine should provide the following movements:

- wheelhead travel (X coordinate);

- longitudinal table travel (Z coordinate);

- grinding wheel rotation (axis Sp1);

- workpiece rotation (axis Sp2);

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Grinding length

2400 mm

-

Centres height

285 mm

-

Grinding wheel dimensions (D x h x d)

750x80...150x305 mm

-

Main drive power

18,5 kW

-

Linear and circular coordinates controllable by CNC

X/Z

-

Discreteness of coordinates X/Z/V/W

0,001 mkm

-

Weight

15000 kg

-

Overall dimensions (length x width x height)

8240 x 4200 x 2150 mm

The machine has a layout with travel table on which is mounted the work piece and grinding wheel-head travel perpendicular to work piece centers axis. The workhead and tailstock with hydraulic drive are mounted on the movable table upper working surface. All of the working bodies travels are carried out over linear guideways by ball screws.

Top table has the rotation ability at an angle (+6º and -3º) that allows to process conical surfaces on details. The top table is based on the lower table, which in turn travels along the bed sliding guideway.

Grinding wheel mechanism is mounted on the workhead.

Grinding wheel periphery dressing is carried out with the help of the dresser diamond, due to moving grinding wheel head and table controlled on the two coordinates.

Hydraulic equipment is made as a separate unit and installed at the back of the machine, and the cooling system is on the left. Electric cabinet is on the machine right side, and in front of the control panel with the SINUMERIK 828d CNC system from Siemens. The base of the processed parts is made in the centers of the front and rear headstock, the axial orientation of the part is made using a touch sensor. Grinding of the part is performed by rotating the workpiece and cross-moving the grinding head.

The grinding surfaces of the grinding wheel, the positioning of the workpiece relative to the grinding circle are made automatically by the control program, the installation and removal of parts is carried out manually. The machine automatically compensates for the amount of removal of the profile of the grinding wheel during editing. The working area of grinding is protected by cabinet-type protection, the front wall of protection has a movable opening door with plexiglass.

When grinding, water-based coolant is used, and the coolant is cleaned using a magnetic separator and a filter conveyor.

- machine assembly (with wheel head, headstock and tailstock);

- coolant supply and cleaning system;

- hydraulic station;

- electric automation cabinet

- control panel with CNC system;

- a set of spare parts and accessories, quick-wear parts for the warranty period (12 months) of operation;

- grinding wheel flanges assembly – 2 sets (1 set is installed on the machine);

- mandrel for static balancing of the abrasive wheel assembly with faceplate;

- device for static balancing of the grinding wheel;

- abrasive wheels 2 pcs. (750 x 305 x 100) mm;

- set of operational and technical documentation in 1 copy;

- universal processing program.

Equipment of the wheel head with a device for dynamic balancing of the grinding wheel. This option includes a flange-type balancing head with a non-contact transmitter, vibration sensor and electronic device. The use of this device allows automatic balancing of the rotating grinding wheel on the machine with minimal imbalance.

Equipped with an exhaust device. When the machine is equipped with a cabinet fence of the working area, it is possible to use a device for sucking aerosol formed during the grinding process. This device is a welded base on which a welded cylinder with a funnel, an engine with an impeller, a filter element, covers with pipes and a sleeve are attached. The exhaust device can operate independently in both manual and automatic mode and allows the removal of aerosol vapors from the treatment area +0.0025 mm.

Equipped with an inprocess gage. The device for active monitoring of cylindrical diameters of processed parts includes a bracket with two measuring heads with orientation function and measuring contacts, as well as an electronic device with a control panel. The electronic device is attached to the machine control panel. The use of an inprocess gage allows you to ensure stable obtaining of the size of the processed diameter within the limits.