- Index

- Catalog

- CIRCULAR GRINDING MACHINES, FACE CIRCULAR GRINDING MACHINES

- SEMIAUTOMATIC CIRCULAR GRINDING MACHINE WITN CNC OSH-651.2.F3

SEMIAUTOMATIC CIRCULAR GRINDING MACHINE WITN CNC OSH-651.2.F3

DESCRIPTION

Special circular grinding semiautomatic machine with CNC model OSH-651.2.F3 is designed for external grinding of cylindrical necks and wheel seats and faces of wheel seats of car axles in automatic line. Field of machine use is the enterprises of serial and large-scale manufacture.

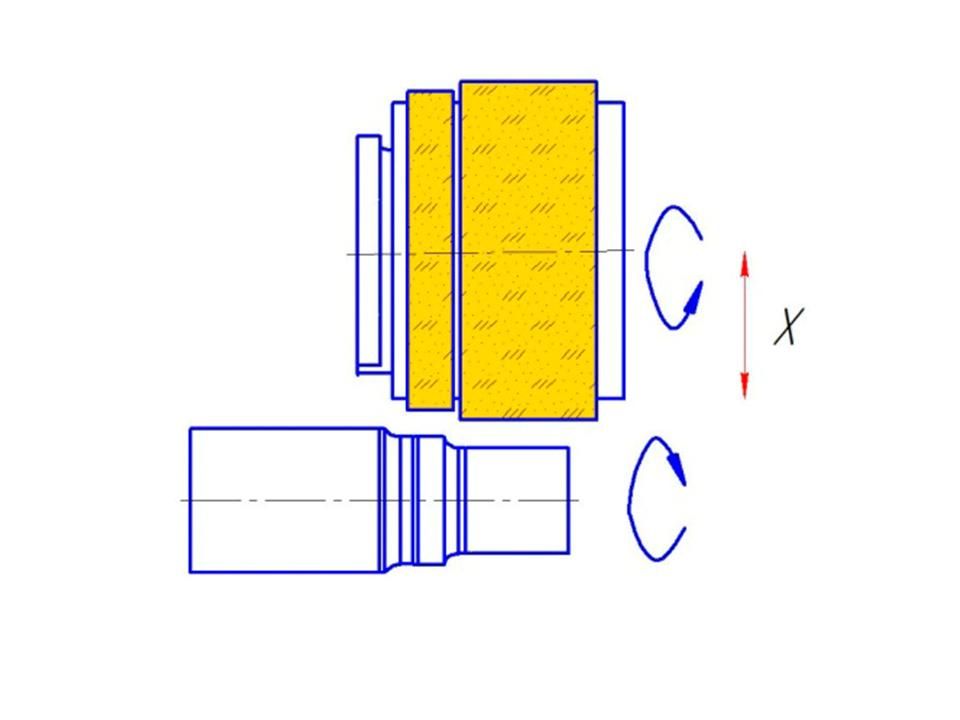

Kinematic diagram of machine must provide the following motions:

- cross travel of wheel head (coordinate Х);

- longitudinal travel of table (coordinate Z);

- rotation of grinding wheel (coordinate Sp);

- rotation of machined part (coordinate Sp1).

Total quantity of machines model OSH-651.2.F3 used in automatic line is two units. Machines are installed successively with their facing parts opposite each other. Each machine is equipped with overhead manipulator with hydraulic and electric equipment for providing removal – installation of machined part. Automation of manipulator operation is ensured by machine CNC system.

DESIGN ADVANTAGES

- CNC system Sinumerik 840Dsl with drives and motors series 1FK of the firm “Siemens”.

- Feedback sensors of the firm “FAGOR”: over programmable coordinate Z (longitudinal travel of table), coordinate Х (cross travel of wheel head).

- Adjustable drive of work head rotation.

- Refrigerating unit of the firm “RITTAL” for electric cabinet.

- Device of grinding wheel dynamic balancing and in-process gauge of the firm “МARРOSS”.

- Contactless and contact transducers of the firm “BALLUFF”.

- High precision angular ball bearings for wheel head spindle, work head spindle.

- Dressing mechanism with two diamond racks.

- Autonomous cooling system with coolant-lubricant feed pump and coolant treatment system by means of magnetic separator and filter-conveyor with filter roll cloth.

- Autonomous system of aerosol sucking off from the machining zone.

- Renishaw probe for part face positioning.

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Length of the workpiece to be installed

2250 mm

-

Outer diameter of the workpiece to be installed

210 mm

-

Main drive power

30 kW

-

Grinding spindle rotation frequency

1280...2130 (stepless reglation)m/min

-

Cutting speed

30...50 m/min

-

Maximum mass of installed work piece (together with mass of fixing elements)

500 kg

-

Grinding wheel spindle rotation frequency

1280...2130 stepless regulation mm

-

Speed of adjustment movements cross of wheel head

5 m/min

-

Speed of adjustment movements longitudinal travel of the table

8 m/min

-

The maximum (new) outer diameter of grinding wheel

750 mm

-

The minimum (worn) diameter of grinding wheel

480 mm

-

Internal diameter of grinding wheel

305 mm

-

Height for grinding the neck and pre-step part of grinding wheel

258 mm

-

Cross travel of the wheel head

420 mm

-

Longitudinal travel of the table

400 mm

-

Discreteness of cross feeds of wheel head

0,001 mm

-

Discreteness of longitudinal feeds of the table

0,001mm

-

Rotation speed of work head spindle

20...300 (stepless regilation) mm

-

Limits of working cross feeds of wheel head

0,1...2000 mm/min

-

Limits of working longitudinal feeds of the table

10...4000 mm/min

-

Overall dimensions of the machine without a manipulator (length х width х height)

5800 x 3850 x 2480 mm

-

Weight of the machine with additional equipment

15 000 kg

-

Weight of the machine without auxiliary equipment

13 000 kg

The machine has an arrangement with a movable table moving in the longitudinal direction and a wheel head moving in the transverse direction.

On the upper table are installed: the headstock, the tailstock, pusher, the mechanism for the grinding wheel dressing with a diamond roller, and the inprocess gage mechanism.

The machine is equipped with a CNC system, an inprocess gage, a device for the grinding wheel dynamic balancing, and a mechanism for orienting the workpiece. The axis of the wheel head spindle is turned to the right at an angle =12. The work head with an electric drive and the tailstock are mounted on the upper working surface of the movable table. Movement of all working bodies is carried out by means of ball-screw gears.

The workpiece is based in the centers of the headstock and tailstock, the axial orientation of the part is performed using a touch sensor on the table.

Grinding of the part is performed by rotating the workpiece and moving the wheel head perpendicular to the center axis.

Surface treatment and grinding wheel dressing are performed automatically according to the control program. The machine automatically compensates for the amount of removal of the grinding wheel profile when dressing. The grinding wheel dressing mechanism is installed on the machine table. Coolant-lubricant on water base is used when grinding.

Delivery set:

- machine assembled (with wheel head, headstock and tailstock);

- coolant feed and treatment system;

- hydraulic station;

- electric cabinet;

- control panel with CNC system;

- set of spare parts and attachments, quick wearing parts for 1 year of operation;

- grinding wheel assembled – 1set (1 set is installed on machine);

- set of operational – technical documentation- 1 copy on paper and additionally 1 copy on electric equipment and programming on electronic carrier;

- attachment for static balancing of grinding wheel and grinding wheel balancing

- 1 шт. for two machines.

- Grinding wheels dressing by rotating diamond roller.