- Index

- Catalog

- SPECIAL PURPOSE MACHINES

- SPECIAL SURFACE GRINDING AUTOMATIC MACHINE WITH CNC MODEL OSH-622.3F3 VERSION 01

SPECIAL SURFACE GRINDING AUTOMATIC MACHINE WITH CNC MODEL OSH-622.3F3 VERSION 01

DESCRIPTION

Automatic surface grinding machine with CNC model OSH-622.3.FЗ version 01 is designed for finishing for double-sided grinding of ceramic parts ' planes (Ø12 mm, h=3mm.)

The scope of application of the machine is large-scale and mass production enterprises.

DESIGN ADVANTAGES

- Siemens SINUMERIK 828D CNC system with Sinamics control drive;

- Linear feedback sensors "FAGOR" for programmable coordinates;

- “MITSUBISHI” current frequency converter for regulating the speed of the wheel head electric motors;

- Transmission of torque along a linear coordinate by means of an “Wittenstein alpha” gearbox;

- Four-position rotary dividing table with vertical axis of rotation (90°division angle);

- Low-voltage equipment manufactured by leading foreign companies;

- Electric cabinet complete with a refrigeration unit of the company "RITTAL”;

- Balluff contactless sensors

- Diamond grinding wheels Ø 500mm. - 2 PCs;

- Cooling system tank with a pump capacity of 400 l / min, with a two-stage coolant cleaning system and a drum-type filter conveyor with a paper belt for cleaning the coolant.

- The CNC system provides the following machine features: - processing of the part according to the program by the method of mortise grinding; - maintaining a predetermined value of the cutting speed

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Dimensions of el`bor borazon material or diamond grinding wheels : (D x H x d)

500 x 5 x 30 mm

-

Dimensions of dressing abrasive wheel and diamond roller: (D x H x d)

-

-

Working feeds limits of upper spindle

1...200 mm/min

-

Working feeds limits of dressing roller

1...200 mm/min

-

Wheel heads spindles drive power

22 kW

-

Overall dimensions (length x width x height)

2000 х 5000 х 2500 mm

-

Mass

7000 kg

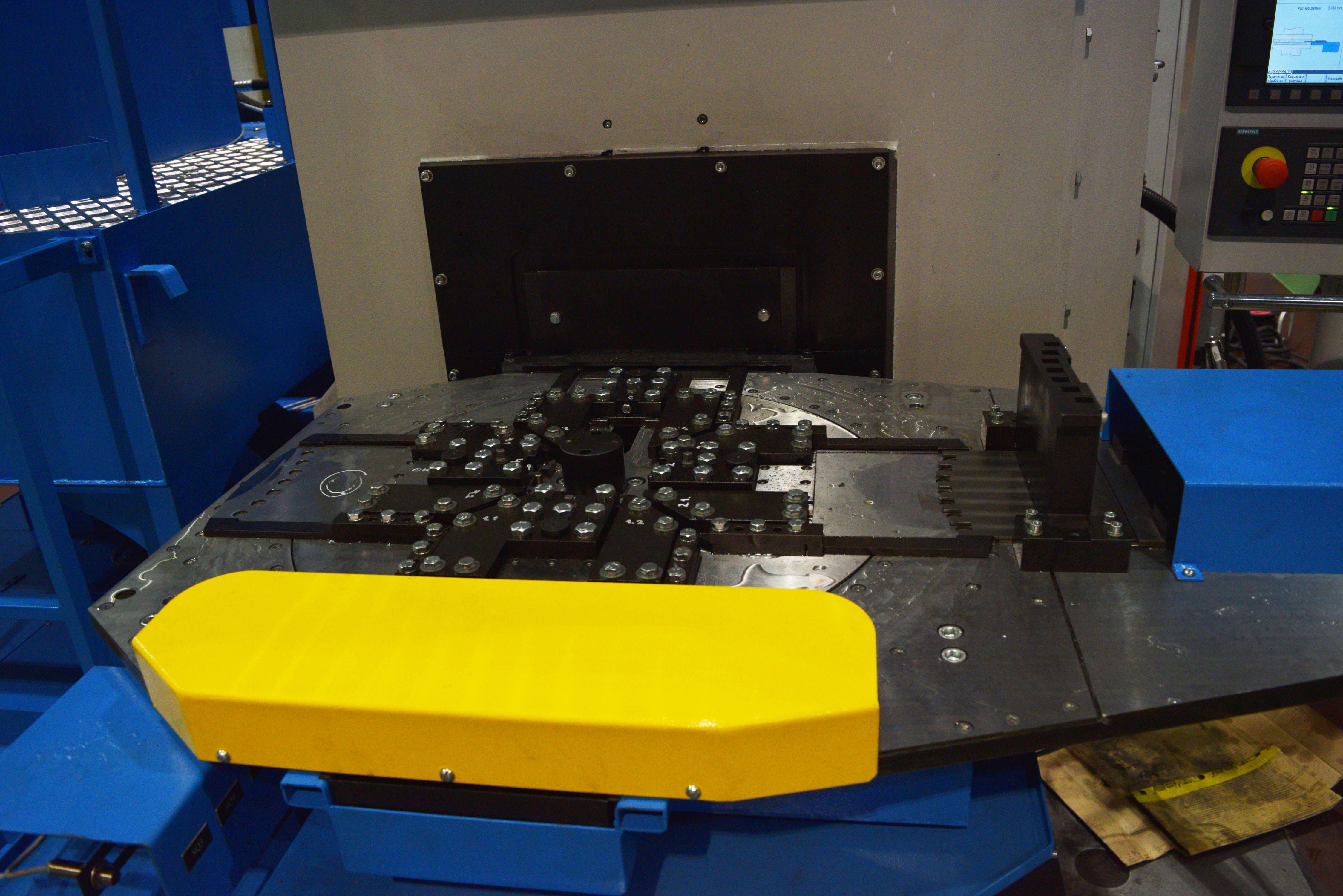

The machine has a layout with a rotary (dividing) round table and two (upper and lower) wheel heads with a vertical axis of rotation.

The base of the machine is the bed. All units, except for the turntable, are placed either inside the bed or on the top plate of it and are covered with a casing and covers, which makes it possible to work on the machine almost safe.

On the right side of the bed the steering console is mounted, which houses the CNC "Sinumerik 828D", behind the panel there is an electric cabinet, the left side has the cooling, and the rear side - the hydraulic station.

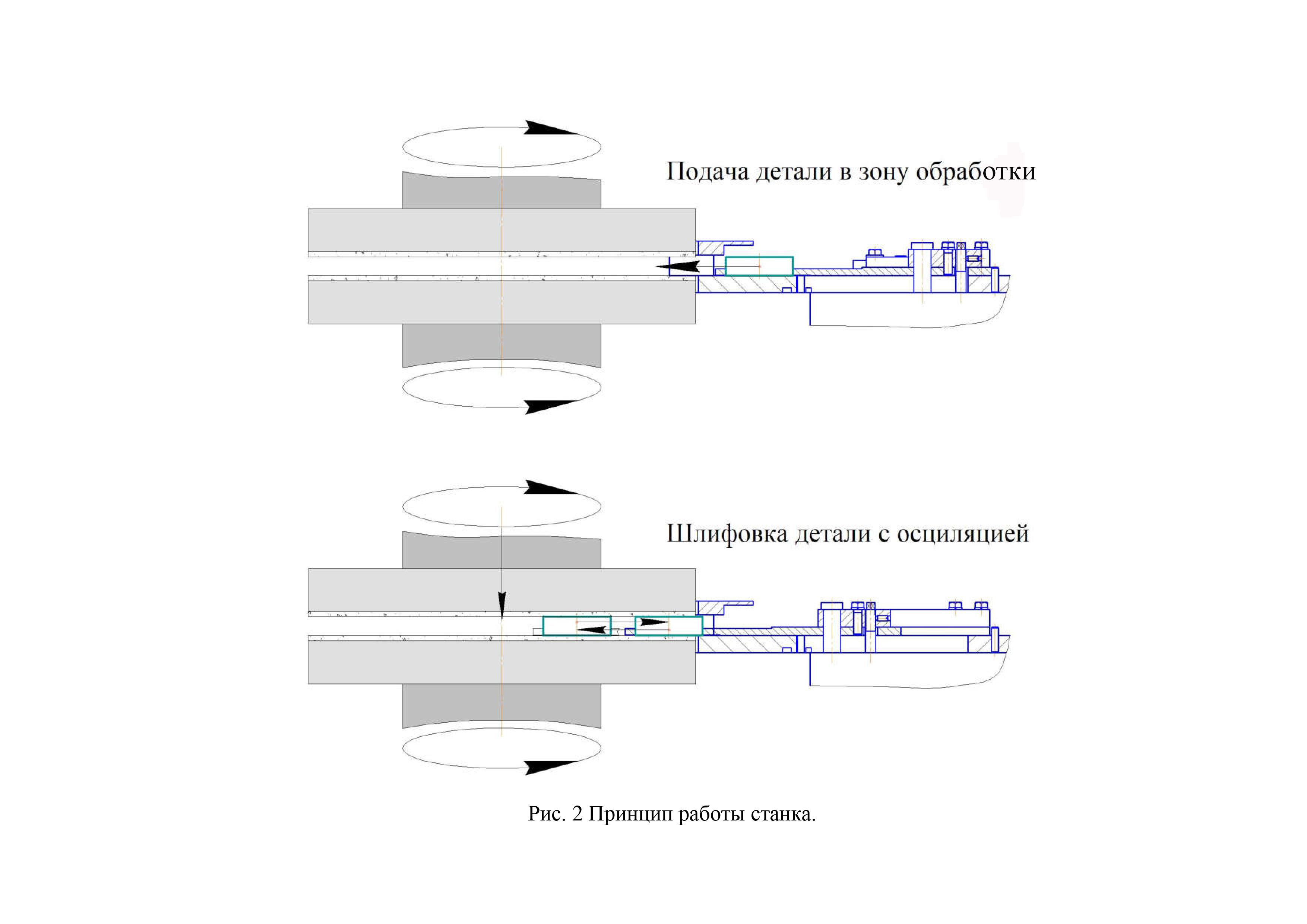

Processing simultaneously of two planes of parts located in the cells of the cassette is performed with the feed to the embedding of the upper wheel head when the oscillating movement of the cassette. The parts are processed with two diamond wheels mounted on the wheel heads. Both spindles can rotate either in one direction or in different directions. The grinding wheels spindles rotation frequency is regulated by frequency current converters. The lower wheel head is rigidly fixed to the machine bed.

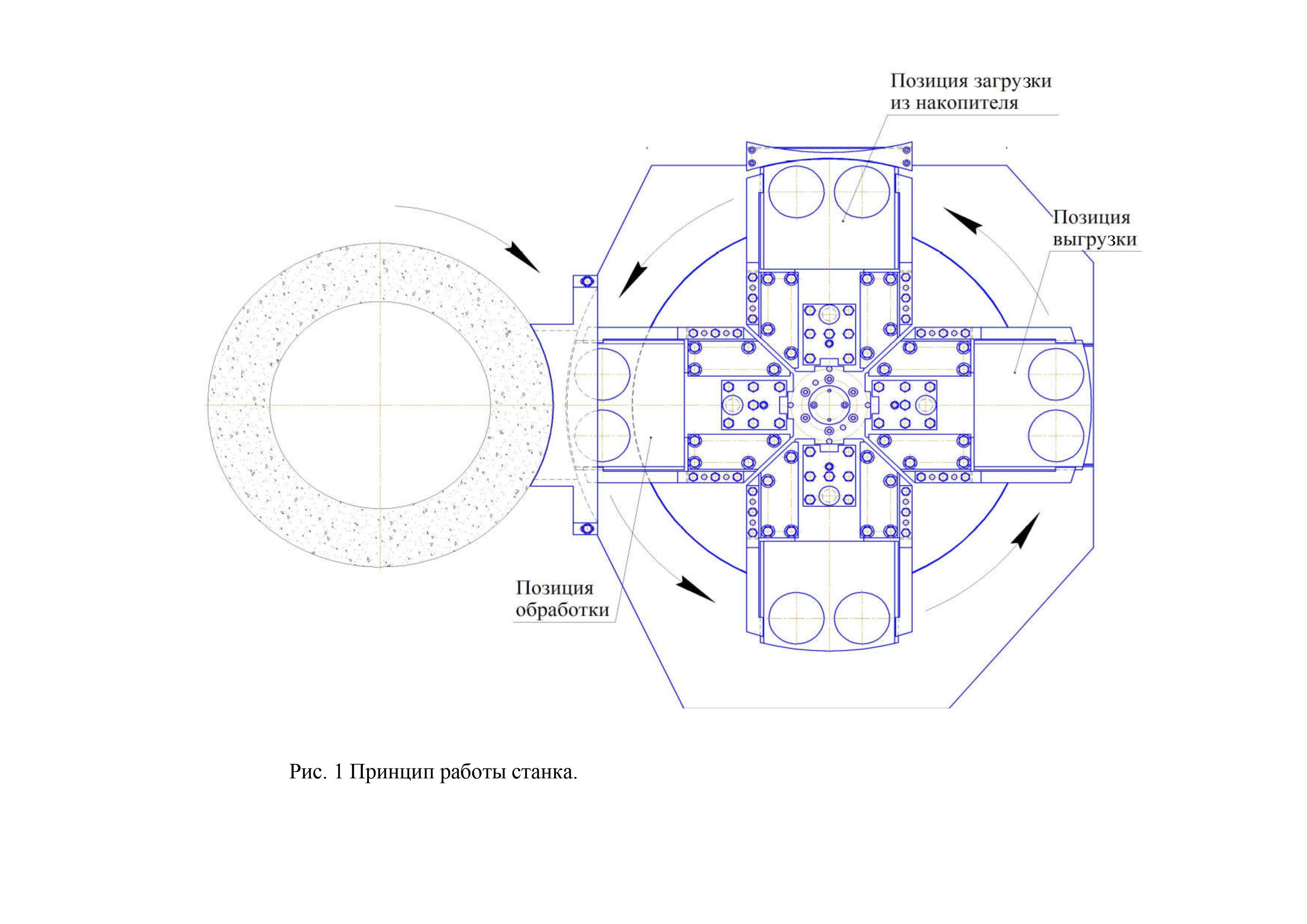

The spindles are mounted on 4 radial and 2 thrust rolling bearings. In the front part of the machine there is a working turntable that performs automatic loading into the cassette, delivery to the work area, oscillation, manual control zone and unloading of parts. Four cassettes are installed on the desktop for placing the processed parts in them. The work table has a 90° positional dividing turn with changing the position of the cassettes: loading, grinding, manual control position and unloading of parts. The parts are unloaded to a special device. Parts are loaded into cassettes from the drive automatically. Control and correction of the size processing is performed by the operator in manual mode. Programmable coordinate V-vertical movement of the upper spindle of the wheel head.

- Machine assembled;

- Electric automation cabinet;

- Control panel with CNC system Sinumerik 828D;

- Cooling system with refrigeration unit;

- Hydrostation;

- Diamond grinding wheels Ø 500mm. - 2 pcs.;

- Mechanisms for automatic loading and unloading of parts;

- Set of spare parts, tools and accessories;

- Set of operational and technical documentation;

- The design of the machine provides for the connection of a device for removing aerosols from the working area.

LIST OF SPARE PARTS:

- mandrel for static balancing of the grinding wheel - 1 pc.;

- adjustable support (shoe) for machine installation - 5 pcs.;

- a set of standard and special keys for maintenance machine during operation and repair - 1 set;

- set of cuffs, rubber rings and seals for mechanical components and hydraulics - 1 set;

- filter elements-3 pcs.

The design of the machine provides for the connection of a device for removing aerosols from the working area.