- Index

- Catalog

- MACHINES FOR DIAMOND- ELECTROCHEMICAL GRINDING

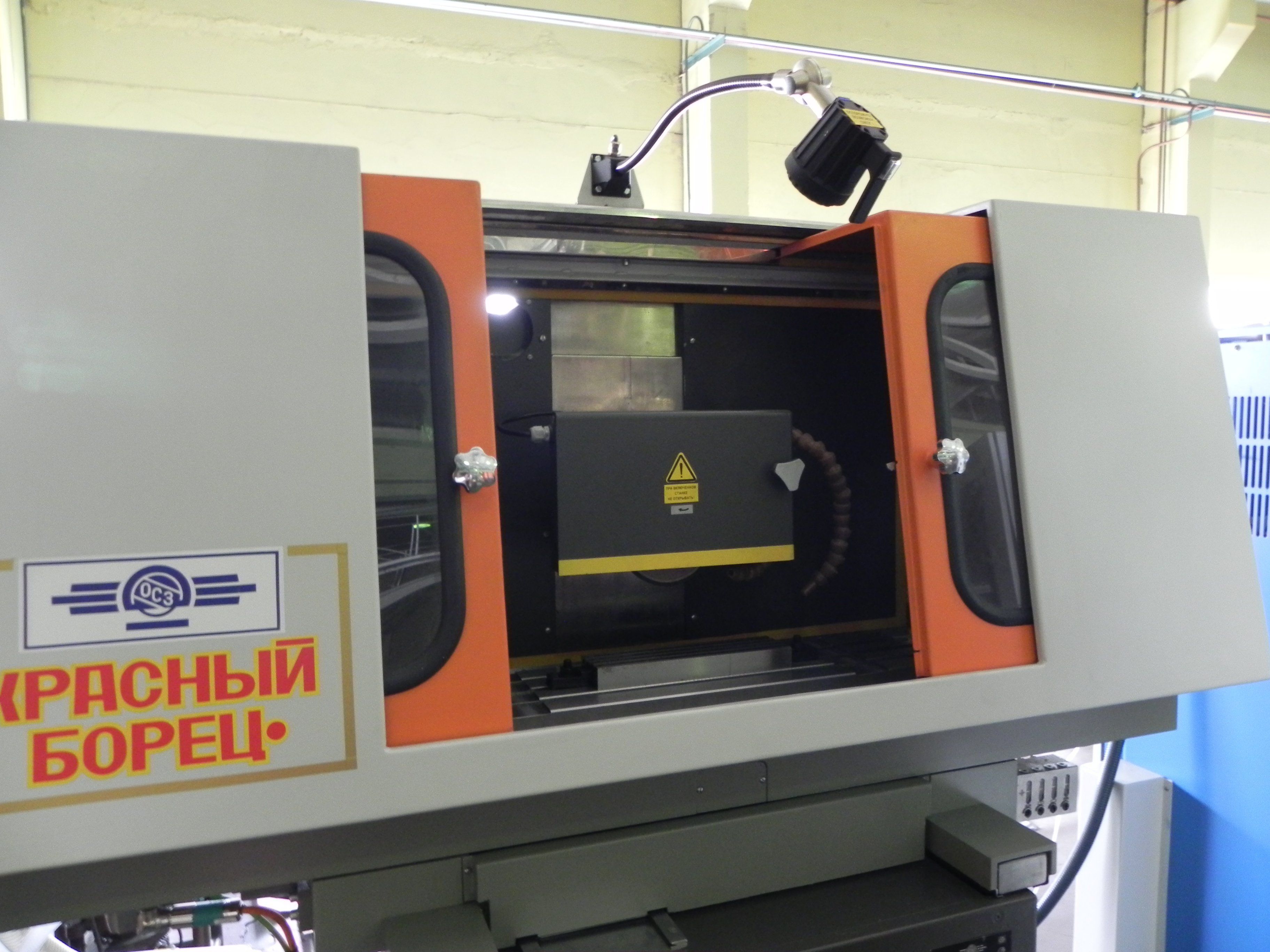

- SEMIAUTOMATIC MACHINE FOR DIAMOND-ELECTROCHEMICAL GRINDING OF SLOTS WITH CNC OSH-625EF3

SEMIAUTOMATIC MACHINE FOR DIAMOND-ELECTROCHEMICAL GRINDING OF SLOTS WITH CNC OSH-625EF3

DESCRIPTION

Semiautomatic machine is designed for electrochemical grinding by diamond wheel of flat and profile surfaces and slots on parts from hard-to-machine materials: hard alloy, heat-resistant alloys and chromium-nickel based steels, titanium alloys, etc.

Machining of surfaces along the whole with removal of all the allowance is realized on semiautomatic machine. Use of technological current source allows to realize the process of electrochemical grinding which includes anodic dissolution of metal and diamond grinding. Machining is realized by diamond conducting wheel with use of electrolyte and feed of potential “+“ and “-“ onto machined part and wheel. Machining the inclined and curvilinear surfaces and slots is possible.

DESIGN ADVANTAGES

- Protection of cutting zone of cabinet type.

- Refinement of electrolyte from suspended particles of machining by means of centrifuge.

- Absence of diamond wheel tear and wear at the expense of electrochemical process in the machining zone.

- Travel of driven elements on roller bearings by rolling ball –screw pairs.

- Linear and circular interpolation over coordinates X, Y and Z.

- Linear travel converters – pilot plant ИС, FAGOR.

- Drives - SINAMICS.

- Wheel head bearings FAG, IBC.

- CNC system SINUMERIK 828D

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Table mirror width

200 mm

-

Table mirror length

450 mm

-

Table maximum travels

550 mm

-

Maximum distance between table mirror and spindle axis

415 mm

-

Main drive power

2,2 kW

-

Speed of table travel

1...250 mm/min

-

Positioning over coordinates accuracy

0,003 mm

-

Overall dimensions (length x width x height)

2400 x 1500 x 1900 mm

-

Mass

2000 kg