- Index

- Catalog

- INTERNAL PROFILE GRINDING MACHINES

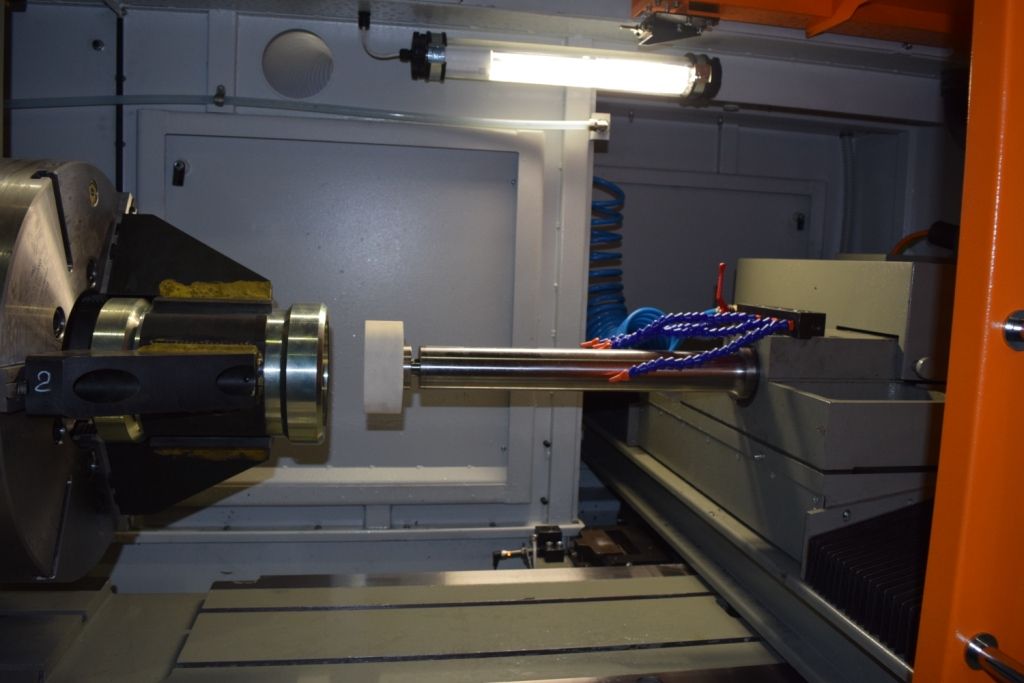

- SEMI-AUTOMATIC INTERNAL GRINDING MACHINE WITH CNC OSH-686F3

SEMI-AUTOMATIC INTERNAL GRINDING MACHINE WITH CNC OSH-686F3

DESCRIPTION

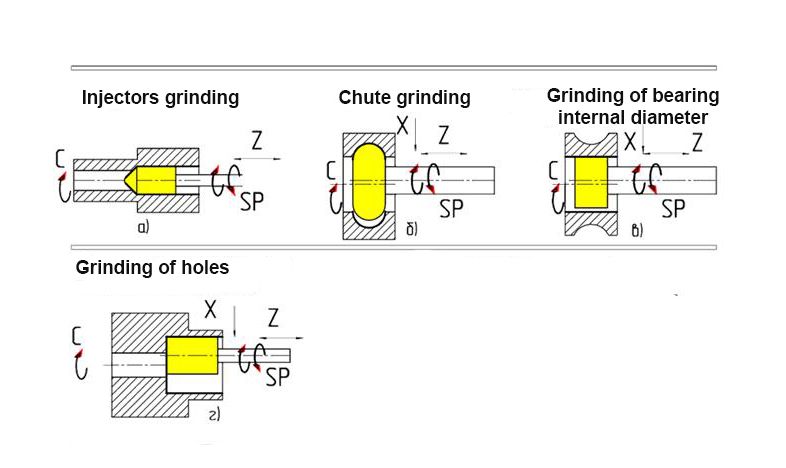

Internal grinding machine with CNC model OSH-686F3 is designed for grinding internal cylindrical and conical surfaces.The scope of the machine is small - scale production. The kinematic scheme of the machine must provide: - transverse movement of the wheel head (X coordinate); - longitudinal movement of the work head (Z coordinate); - rotation of the work head spindle (coordinate Sp1);

- rotation of the grinding wheel (coordinate Sp2);

- movement of the dressing mechanism to the processing area;

DESIGN ADVANTAGES

- System of CNC Sinumerik 802Dsl of the firm "Siemens" with servo drives Sinamics.

- Portable control panel with electronic flywheel.

- FAGOR feedback sensor for the X-coordinate (transverse movement of the grinding wheel)

- Internal grinding spindle of the firm FISCHER – 30 000 rpm

- Refrigerating unit of electric cabinet of the firm “Rittal”.

- High precision gapless ball-screw transmissions of the firm “Mikron” in the feed drives mechanisms.

- High precision angular contact ball bearings of the company "IBC" for the work head spindle

- Dressing mechanism assembled with dresser diamond.

- Coolant cleaning device using a magnetic separator and paper filter conveyor.

- The cabinet-type protection of work area.

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Length of machined surfaces

150 mm

-

Internal diameter of machined surfaces

200 mm

-

External diameter of machined surfaces

180 mm

-

External diameter of grinding wheel installed on semiautomatic machine

10...63 mm

-

Internal diameter of grinding wheel installed on semiautomatic machine

6...20 mm

-

Electric spindle rotation frequencies limits

75000...105000 min-1

-

Work head spindle rotation frequency

20...800 min-1

-

Axis

B

-

Overall dimensions (length x width x height)

3500 х 3700 х 2000 mm

-

Mass

4000 kg

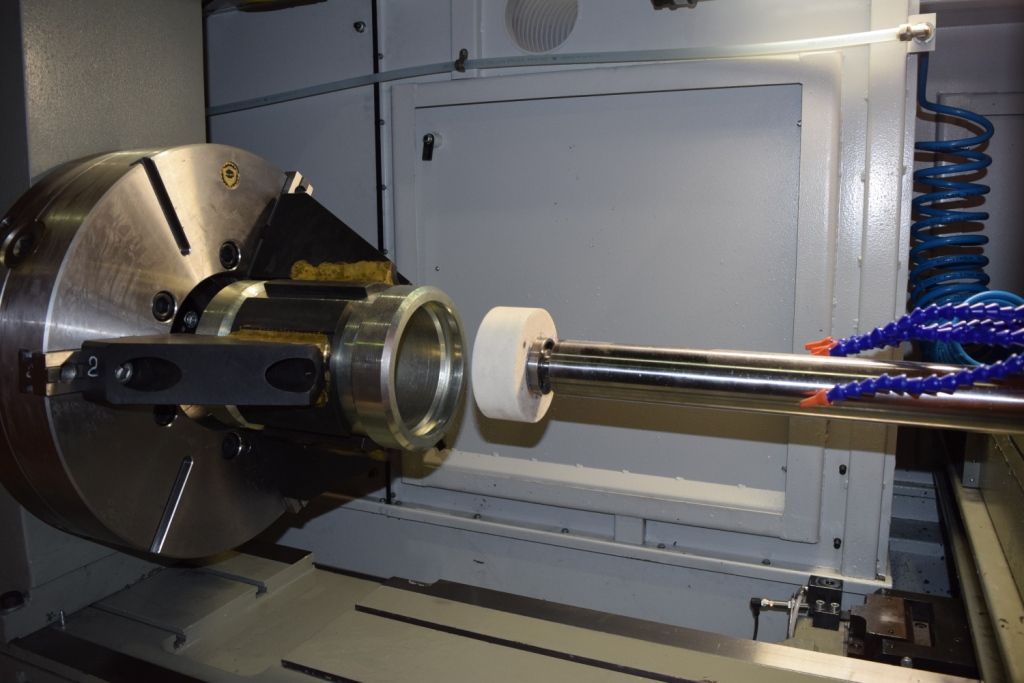

The machine has a layout with moving wheel head in the transverse direction, longitudinal movement of the workhead relative to the axis of the grinding wheel and the rotation of the workhead spindle. The processed part is installed in the work head cartridge. A support cradle can be installed on the machine table. The part is installed manually.

All working bodies are moved by means of ball-screw pairs. The base of the machine is the bed on which the main components and mechanisms are installed. A longitudinal table is installed on the rolling guides of the bed. There is a cross table on the cross - beam guides, and there also fixed:

- longitudinal and cross travels mechanisms;

- mechanism of longitudinal travels limitation;

- the mechanism of reference and limit of the transverse travels;

- fencing of the working area.

The cross table provides a cross movement of the headstock of the grinding spindle installed on it. Movement is carried out on steel hardened linear rolling guides by means of a backlash-free high-precision ball-screw transmission.

The grinding wheel periphery dressing is carried out with a dresser diamond dresser, the device for dressing is fixed on the longitudinal table.

Surface treatment and dressing of the grinding wheel is performed automatically according to the control program, installation and removal of the part are carried out manually. The machine automatically compensates for the amount of removal of the profile of the grinding wheel during dressing.

On the rolling guides, a longitudinal table is moved, which performs an oscillatory movement with the possibility of stepless and precise supply. An upper turntable is installed on the longitudinal table. On the working surface of the longitudinal table, the work head and the supporting rest are installed. The upper table can be rotated horizontally at an angle of ±2°. The work head can be rotated at an angle of -7°...+8°.

A hydraulic three-cam self-centering chuck with replaceable cams can be used to install parts.

The hydraulic lubrication station and coolant tank are installed behind the machine.

The working area of grinding is protected by cabinet-type protection, the front wall of the protection has a movable opening door with plexiglass.

In front, to the right of the machine, there is a CNC control panel. The Siemens Sinumerik 802Dsl CNC system must provide the following machine capabilities:

- part processing by rotating the workpiece and moving the wheel head;

- maintaining the set value of the cutting speed and the set speed of the workpiece.

For the convenience of the operator, a universal technological program is installed on the machine. In the dialog mode, using special "masks", the operator sets:

- the dimensions of the surface to be processed;

- removable allowance;

- finishing allowance;

- values of roughing and finishing feeds and speeds;

- number of sparkling sessions;

- parameters and number of the grinding wheel dressings during processing.

- machine assembly;

- coolant supply and cleaning system;

- hydraulic station;

- electric automation cabinet;

- control panel with CNC system;

- three-cam chuck;

- set of spare parts, tools and accessories;

- set of operational and technical documentation;

Special FAV42.80R630 belt-driven spindle with a speed of 15,000 min-1, made by FISCHER (FORTUNA) for processing deep holes D of hole≥50 mm. and the length L of hole <420mm

Lunette 40...100 mm.

- Lunette 100...300 mm

Limits of spindle rotation frequencies

IT IS COMPLETED WITH REPLACEABLE FORTUNES