- Index

- Catalog

- GRINDING MACHINE WITH ROUND ROTARY TABLE AND VERTICAL SPINDLE

- INTERNAL GRINDING MACHINE WITH CNC WITH ROUND TABLE AND VERTICAL SPINDLE OSH-642 VERSION 18

INTERNAL GRINDING MACHINE WITH CNC WITH ROUND TABLE AND VERTICAL SPINDLE OSH-642 VERSION 18

DESCRIPTION

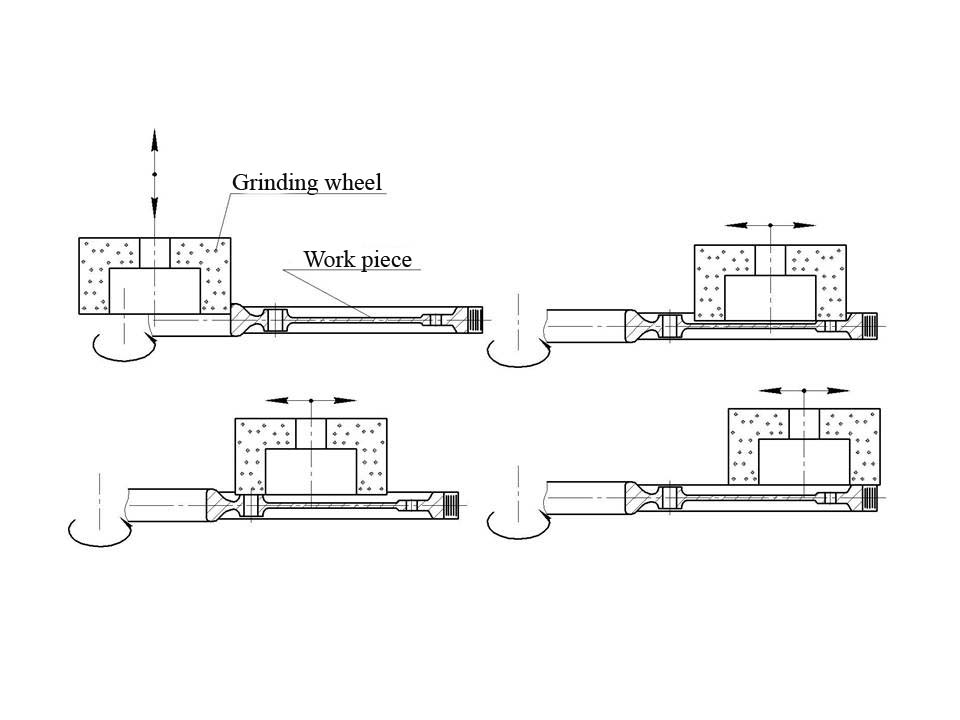

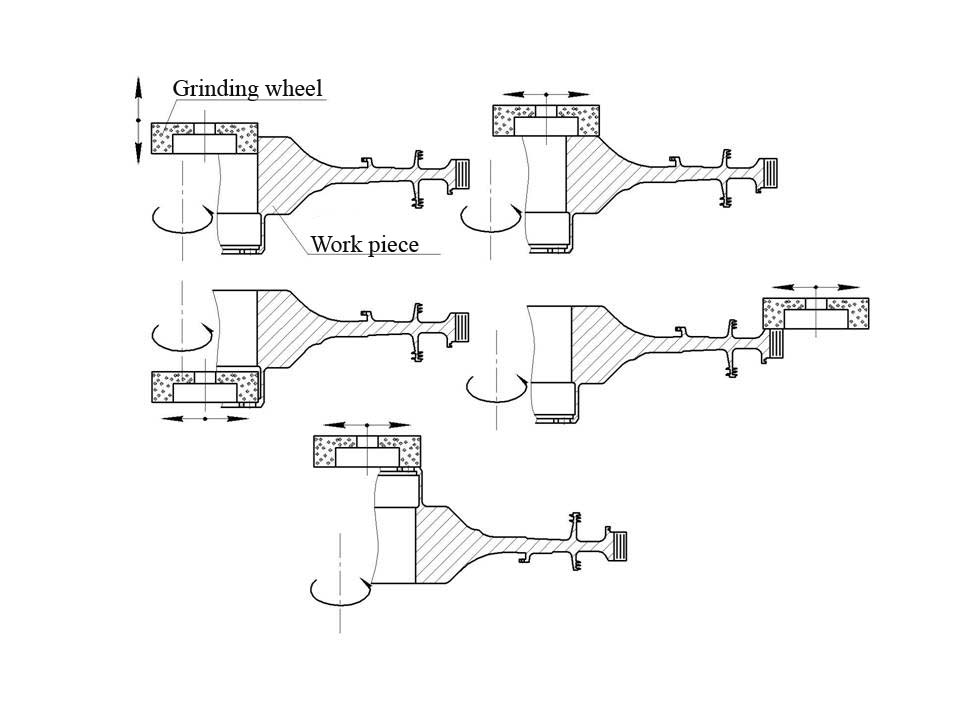

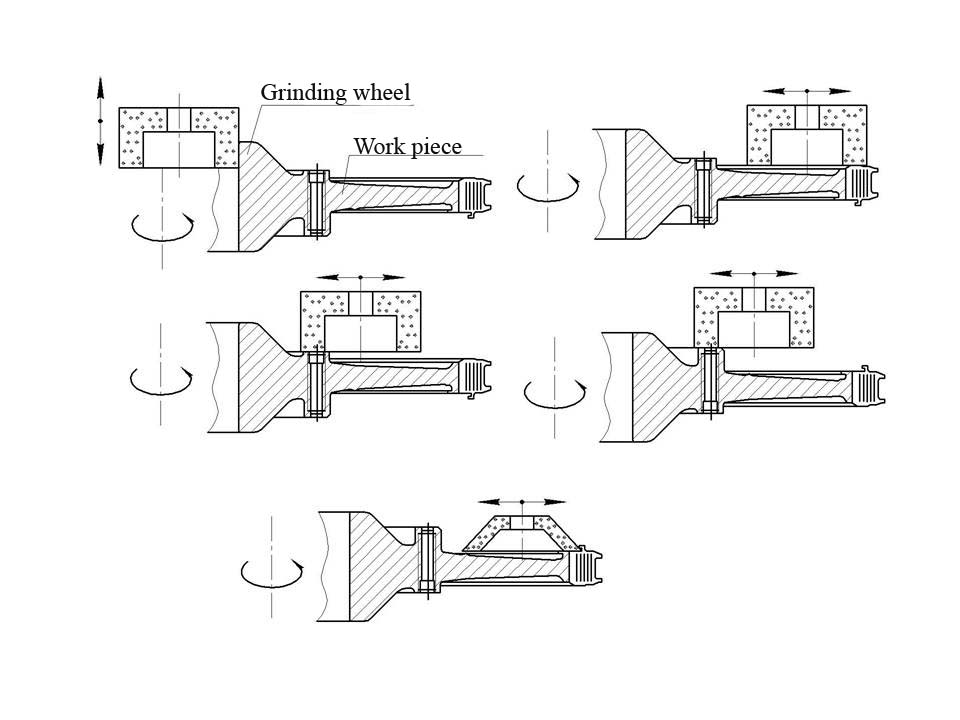

Special internal grinding semiautomatic machine with CNC with round table and vertical spindle model OSH-642 version 18 is designed for grinding internal holes, external diameters and adjacent faces of parts type of rings, cups, sleeves.

Kinematic diagram of machine must provide the following motions:

- grinding wheel rotation;

- wheel head vertical travel;

- column cross travel;

- rotation of rotary table;

- dressing mechanism turning into working and initial position.

DESIGN ADVANTAGES

- Execution of all basic parts (base, bed, column, wheel head body) in the form of box shaped casts provides high rigidity and accordingly accuracy of processing to machine

- Closed roller linear slideways are used for column travel in cross direction and wheel head in vertical direction

- Use of rotary table with vertical axis of rotation with installed on it face plate and adjustment of rotation frequency

- Inprocess gage of the firm “Marposs” is used for control of dimensions of parts machined holes

- Rotary table face plate rotation is realized from conic reduction gear of the firm “Wittenstein alpha” SK-140 fastened on the bracket of the left wall of the bed

- Precision high –speed electric spindle is used as grinding spindle. Lubrication is oil mist, water cooling, spindle revolutions adjustment is by current frequency converter

- Column travel drive is from programmable drive Sinamics of the firm “Siemens” through belt transmission onto rolling screw-nut

- Use of converters of linear travels over coordinates X and Z of the firm “Fagor”

- Refrigerating unit is used for providing heatset of coolant-lubricant

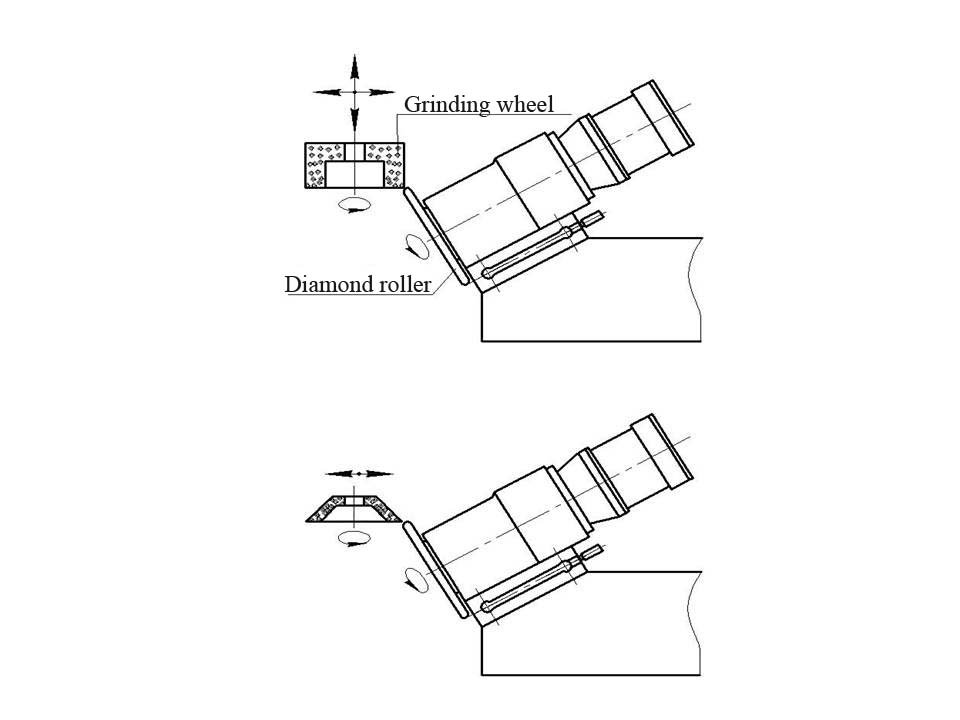

- Grinding wheel dressing is realized by rotating diamond roller, dressing mechanism is rotary and is fastened on horizontal pad in the bed niche

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Diameter of working surface of round table

800 mm

-

Article table rotation frequency

1...95 mm/min

-

Maximum height of installed on table mirror work piece

250 mm

-

Grinding wheel diameter

80...125 mm

-

Grinding wheel height

50 mm

-

Grinding wheel bore diameter

20...32 mm

-

Main drive power

5,5 (fortuna) kW

-

Grinding spindle rotation frequency

2000...16000 Rpm

-

Discreteness of vertical and cross feeds

0,001 mkm

-

Cutting speed

35 m/s

-

External maximum diameter of machined workpiece

800 mm

-

Table turn slope angle

+-5 degrees

-

Internal minimum diameter of machined workpiece

90 mm

-

Coolant-lubricant feed pump productivity

100 L/min

-

Coolant treatment

magnetic separator

-

Coolant-lubricant tank capacity

450 L

-

Speed of wheel head travel

1600 mm/min

-

Speed of column travel

4000 mm/min

-

Overall dimensions (length x width x height)

2950 x 3200 x 2650 mm

-

Mass

5300 kg

Execution of all basic parts (base, bed, column, wheel head body) in the form of box shaped casts provides high rigidity and accordingly accuracy of processing to machine.

Precision high –speed electric spindle is used as grinding spindle. Lubrication is oil mist, water cooling, spindle revolutions adjustment is by current frequency converter.

Closed roller linear slideways are used for column travel in cross direction and wheel head in vertical direction.

CNC system:

- control system – “Sinumerik 828D of the firm Siemens;

- Operator’s control desk is of the firm Siemens;

- feeds electric drives – servo drives Sinamics of the firm Siemens;

- low voltage equipment of the firm Siemens;

- limit switches of the firm Balluff.

Machine delivery set consists of :

- machine assembled (with rotary table, wheel head);

- working zone enclosure;

- coolant feed and treatment system;

- hydraulic station;

- electric cabinet;

- grinding wheel dressing mechanism with diamond roller;

- control desk with CNC system;

- electric spindle cooling system;

- set of quick wearing parts and tools;

- universal software of parts machining;

- set of operational – technical documentation.

Rotary grinding wheel dressing by dresser diamonds mechanism.

Equipping with inprocess gage of the diameters of internal holes processed on the machine.

Machine equipping with electromagnetic chuck with the diameter 1200 mm and device of current supply to the chuck.

Equipping with manual jaw chuck installed on rotary table face plate for basing and fastening the machined parts.