- Index

- Catalog

- GRINDING MACHINE WITH ROUND ROTARY TABLE AND VERTICAL SPINDLE

- SEMIAUTOMATIC INTERNAL GRINDING MACHINE WITH ROUND TABLE AND VERTICAL SPINDLE WITH CNC MODEL OSH-623F3

SEMIAUTOMATIC INTERNAL GRINDING MACHINE WITH ROUND TABLE AND VERTICAL SPINDLE WITH CNC MODEL OSH-623F3

DESCRIPTION

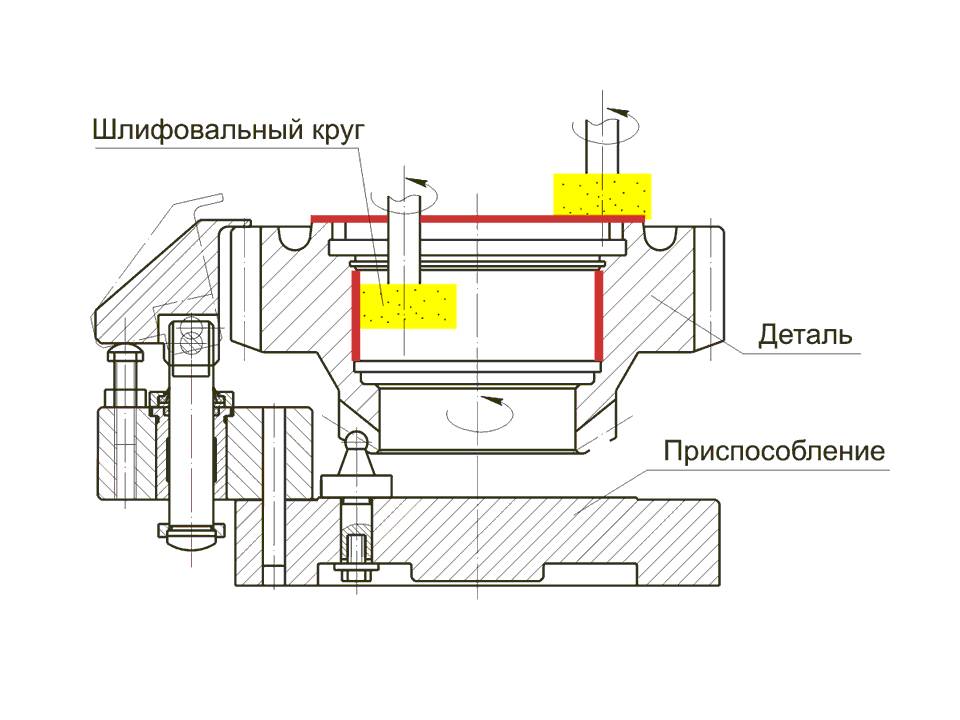

Semiautomatic internal grinding machine with round table and vertical spindle with CNC model OSH-623F3 is designed for grinding of internal and external cylindrical surfaces of parts type of bodies of revolution by abrasive or CBN grinding wheels.

Parts machining on semiautomatic machine is produced at the expense of vertical travel (feed) of grinding wheel and circular rotation of part with oscillation or longitudinal feed. Machining of faces can be realized by single-pass creep feed method at radial feed (removal of allowance at single pass) or as usual face grinding with dressing and grinding wheel undercut as per NC program with compensation.

Field of use of machine is serial and small branch production.

Kinematic diagram of machine must provide the following motions:

- rotation of grinding wheel from electric spindle (axis Sp1);

- vertical travel of wheel head from servo motor (coordinate Z);

- compound slide travel with table from servo motor (coordinate X);

- rotation of faceplate of rotary table from servo motor (axis Sp2);

- rotation of dressing mechanism diamond roller from hydraulic motor.

DESIGN ADVANTAGES

- CNC system «Sinumerik-828D» with drives Sinamics of the firm «Siemens»

- Electric spindle of the firm «FISCHER» equipped with frequency converter of the firm «VACON»

- Low voltage equipment of the firm «Siemens»

- Contactless sensors and end switches of the firm «Balluff»

- Electric cabinet of own production with refrigerating unit of nthe firm «RITTAL»

- Closed linear rolling element guide ways.

- High precision gapless bal-screw pairs in feeds drives mechanisms

- Touch sensor of the firm «Renishaw» (for determination of part position)

- Dressing mechanism with diamond roller as a unit

- Converters of linear and circular travels over controllable coordinates of the firm «Fagor»

- Universal control program (CP) for machining sizing in step-by-step mode with possibility of entering and storing the CPs on separate parts

- Coolant treatment device by magnetic separator

- Plant for aerosol exhaust from machining zone

- Working zone protection of cabinet type

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Round table working surface diameter

400/600 mm

-

Wheel head working feeds

170 mm

-

Compound slide working feeds

280 mm

-

Maximum mass of installed work piece (together with attachment and electromagnetic chuck)

100 kg

-

Grinding wheel diameter

25...80 mm

-

Grinding wheel height

40 mm

-

Grinding wheel bore diameter

10...32 mm

-

Main drive power

22,0 (electric spindle) kW

-

Grinding spindle rotation frequency

6000...30000 mm/min

-

Maximum height of machined surface

110 mm

-

External diameter of installed diamond roller

125 mm

-

Internal diameter of installed diamond roller

32 mm

-

Radius at the top of installed diamond roller

5 mm

-

Discreteness of vertical and cross feeds

0,001 mkm

-

Cutting speed

35 m/s

-

External maximum diameter of machined workpiece

400/600 mm

-

Table turn slope angle

-

-

Internal minimum diameter of machined workpiece

20 mm

-

Coolant-lubricant feed pump productivity

100 L/min

-

Coolant treatment

magnetic separator

-

Manufactured article table rotation frequency

5...250/1...95 mm/min

-

Coolant-lubricant tank capacity

450 L

-

Speed of wheel head travel

800 mm/min

-

Speed of column travel

4000 mm/min

-

Overall dimensions (length x width x height)

2800 x 2300 x 2140 mm

-

Mass

4400 kg

Machine has an arrangement with traveling wheel head in vertical direction and cross travel of compound slide on which rotary table is installed. Machined part is installed on rotary table in attachment. Travels of all driven elements are realized by ball-screw pairs.

Base of the machine is a bed on left upper pads of which roller guide ways are installed over which compound slide with installed on it enclosure.

Dressing mechanism (to the left) and rotary table (to the right) with vertical rotation axis faceplate of which bases the changeable adjustments designed for machining the concrete part are installed on compound slide plate.

Column is fastened on the right upper pad of bed with vertical linear rolling guide ways for travel of wheel head on which electric spindle is mounted.

Vertical feed mechanism is fastened on column lower pad.

Cross feed mechanism is located inside the bed and mechanism of cross travels reading is in the middle under compound slide.

Cooling system located from behind, electric cabinet installed from the right side of the operator and hydraulic station located from the right side of the bed relate to attached equipment of the machine.

Machining of surfaces and grinding wheel dressing is produced in automatic mode according to control program (CP), installation and removal of the part is realized by a special customer’s hoist cable device or manually.

Automatic compensation of grinding wheel profile removal value is realized during dressing. Grinding wheel dressing is realized by rotating diamond roller R=5 mm.

Working zone of grinding is enclosed by cabinet type protection, the front wall of protection has movable opening door with plexiglass.

Coolant-lubricant on water base is used during grinding, coolant treatment is realized by magnetic separator.

Machine painting is enamel SF-48 0000/01, colour is white-blue.

CNC system

CNC system "Sinumerik 828D” of the firm “Siemens” must provide the following capabilities of the machine: - machining the part profile by method of infeed grinding at the expense of machined part rotation and wheel head feed over linear axes of coordinates.

- machine assembled;

- coolant feed and treatment system;

- hydraulic station;

- electric automation cabinet with control panel and CNC system;

- aerosol exhausting unit;

- electric spindle cooling system;

- set of spare parts and attachments, quick wearing parts for 2 years of operation;

- grinding arbours – 3 pcs.;

- abrasive wheels - 6-80х40х20 - 10 pcs.;

- set of operational-technical documentation.

Grinding wheel dressing mechanism by dresser diamonds

Equipping with inprocess gage of diameters of internal holes processed on the machine.

Equipping with manual jaw chuck installed on faceplate of rotary table for basing and fastening of machined parts with maximum diameter 400 mm.

Equipping the machine with coolant feed and treatment with use of magnetic separator and filter –conveyor with roll filter cloth.

Equipping the machine with one rotor –type centrifuge for coolant treatment.

When grinding the internal holes of cogged wheels and gears the machine is equipped with a special attachment with automatic mechanical clamping and hydraulic unclamping.