- Index

- Catalog

- CIRCULAR GRINDING MACHINES

- UNIVERSAL CIRCULAR GRINDING MACHINE WITH MASTER CONTROLLER OSH-510F2

UNIVERSAL CIRCULAR GRINDING MACHINE WITH MASTER CONTROLLER OSH-510F2

DESCRIPTION

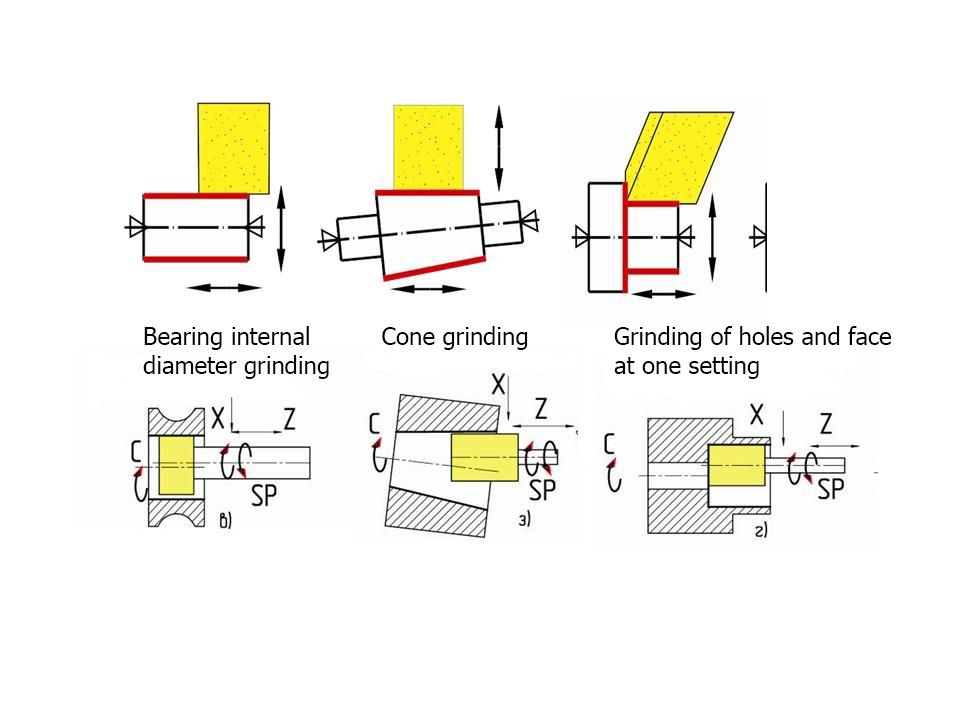

Designed for external and internal grinding of cylindrical, conical and end surfaces in the chuck and centers.

The kinematics of the machine provides the following movements:

- rotation of the circular grinding spindle (Sp axis);

- cross movement of the wheel head (X coordinate);

- longitudinal movement of the table (Z coordinate);

- rotation of the workpiece (axis Sp1);

-rotation of the internal grinding spindle (SP2 axis);

DESIGN ADVANTAGES

- The machine has manual and automatic control from the command controller .

- Contactless sensors of the company “Balluff”.

- Low-voltage equipment manufactured by Siemens.

- Fagor linear displacement converters as feedback.

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Diameter of the workpiece to be installed in the centers

100 mm

-

Length of the workpiece to be installed in the centers

250 mm

-

Diameter of the workpiece to be installed in the chuck

70 mm

-

Length of the workpiece to be installed in the chuck

150 mm

-

Main drive power

2,2 kW

-

Diameter of grinding in the centers

100 mm

-

Length of grinding in the centers

225 mm

-

Diameter of grinding in the chuck when external grinding

70mm

-

Length of grinding in the chuck when external grinding

160 mm

-

Diameter of grinding in the chuck when internal grinding

8...40 mm

-

Length of grinding in the chuck when internal grinding

50 mm

-

Mass of workpiece in the centers

7 kg

-

Mass of workpiece in the chuck

5 kg

-

Height of centers

80 mm

-

Outer diameter of the grinding wheel for external grinding

250 mm

-

Inner diameter of the grinding wheel for external grinding

76 mm

-

Height of the grinding wheel for external grinding

25 mm

-

Outer diameter of the grinding wheel for internal grinding

3...32 mm

-

Height of the grinding wheel for internal grinding

10...40 mm

-

Angle of rotation of the upper table clockwise/counterclockwise

+3/-3 degree

-

The angle of rotation of the work head in clockwise/counterclockwise direction

-30/+90 degree

-

Angle of the wheel head rotation

+-20 degree

-

The product rotation frequency

10...500 rpm

-

Spindle power for internal processing

0,75 kW

-

Speed of the internal grinding spindle

4000...24000 rpm

-

Accuracy processing parameters

GOST 11654-90 OF MACHINES OF HIGH ACCURACY CLASS

-

Deviation from the constancy of the diameter at a length of 225 mm in the longitudinal section when processing in centers

0,4 mkm

-

Roundness tolerance in the processing centers

1,0 mkm

-

Roundness tolerance when processing in the chuck

1,6 mkm

-

Roughness of the cylindrical outer surface

0,32 RA

-

Roughness of the cylindrical inner surface

0,32 RA

-

Roughness of the flat end face

0,16 RA

-

Overall dimensions (length x width x height)

1760х2140х1520 mm

-

Mass

2000 kg

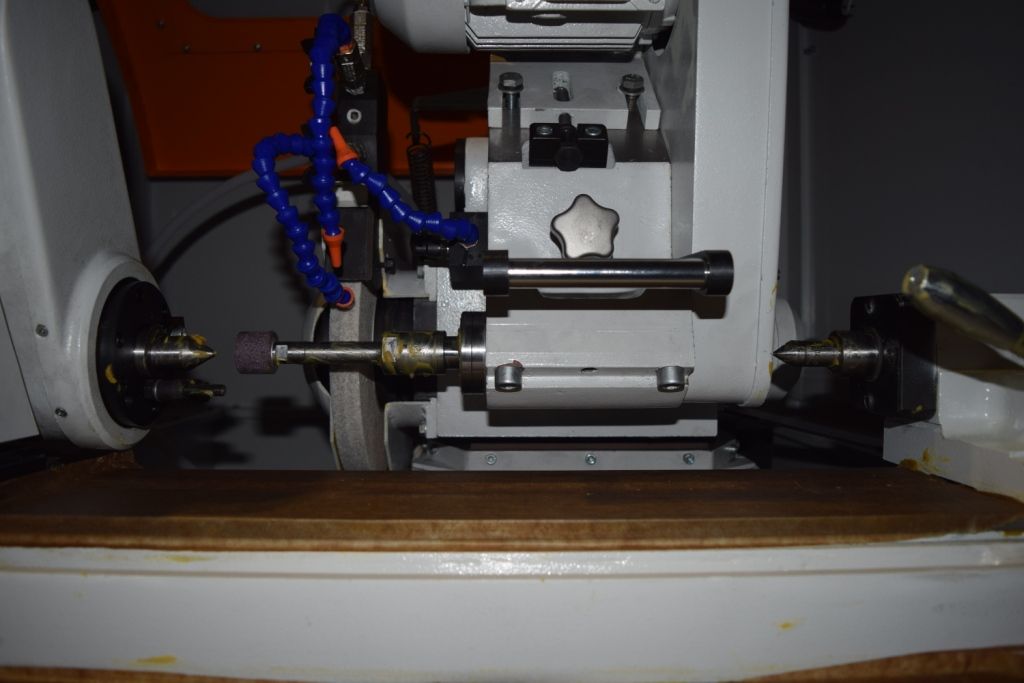

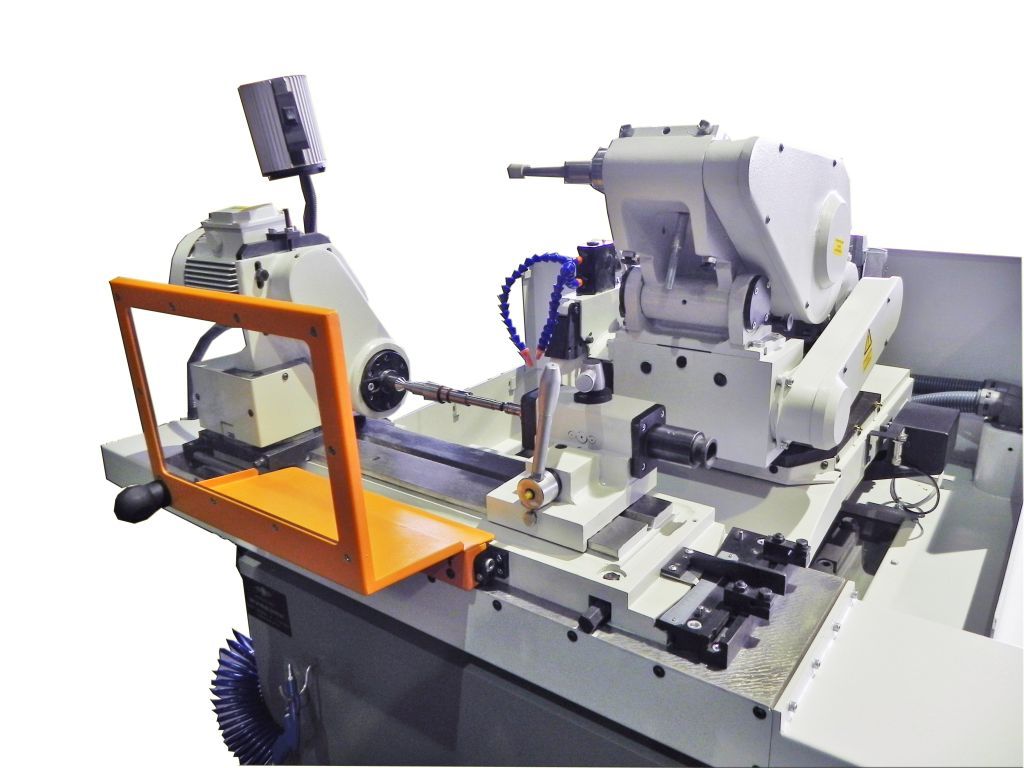

The machine has manual and automatic control from the command controller. The machine has a layout with a moving table on which the workpiece is installed and the movement of the wheel head perpendicular to the axis of the centers relative to the workpiece. Basing of the processed parts is made in the centers of the headstock and tailstock or in the chuck.

The working area of grinding is protected by an open type of protection, the front wall of the protection has a movable opening door with plexiglass.

The work head and the tailstock are attached to the upper working surface of the movable table. The wheel head is moved along the linear rolling guides by means of a ball-screw transmission. The work head has the option of manual rotation to 90 degrees, wheel head has two spindles for external and internal grinding, it also has the ability to manually rotate an angle of ±30. The internal grinding spindle is rotary. The upper table can be rotated at an angle (3 ° clockwise and -3 ° counterclockwise) and is based on the lower table, which in turn moves along the slide rails of the frame.

The work head and the tailstock are attached to the upper working surface of the movable table. The wheel head is moved along the linear rolling guides by means of a ball-screw transmission. The work head has the option of manual rotation to 90 degrees, wheel head has two spindles for external and internal grinding, it also has the ability to manually rotate at an angle of ±30. The internal grinding spindle is rotary. The upper table can be rotated at an angle (3 ° clockwise and -3 ° counterclockwise) and is based on the lower table, which in turn moves along the slide rails of the bed. The periphery and end of the grinding wheel are dressed using dresser diamonds of the dressing mechanism installed on the upper table due to the longitudinal movement of the table and the transverse movement of the grinding wheel (linear interpolation by two coordinates).

Hydraulic equipment is made by a separate unit and installed at the back of the machine, and the cooling system is on the left. There is an electric cabinet on the right side of the machine.

In front of the machine, a combined control panel with a Siemens operator panel and a machine control panel with electronic flywheels, a joystick and control buttons are installed on the electric cabinet.

When grinding, water-based coolant is used, and the coolant is cleaned using a magnetic separator and a filter conveyor. The treatment zone is supplied with coolant at a pressure of P = 2 ATM, the pump capacity is Q = 30 l/min. Proximity sensors of the company "Balluff". .

Low-voltage equipment of the company "Siemens". .

As a feedback, “Fagor” linear displacement converters are used.

Standard delivery set:

- machine assembled ( with wheel head, headstock and tailstock);

- coolant supply and cleaning system (complete with magnetic separator and filter conveyor);

- lubrication hydraulic station;

- electric automation cabinet;

- luminaire;

- control panel with operator panel and programmable logic controller (S7-1200 by “Siemens”);

- arbour for internal grinding wheel;

- grinding wheels GOST R 52781-2007:

- 1-250 x 25 x 76 (mm) – 1 pc.

- 32 x 25 x 10 (mm) – 10 pcs.

- dresser diamond 3908-0247 – 3 pcs. (installed on the machine);

- three-cam chuck with a diameter of 80 mm/100 mm – 1 pc.;

- grinding wheel flanges – 2 sets (1 set is installed on the machine);

- open type guard of the working zone;

- gun for air blowing;

- set of spare parts and accessories, quick wearing parts for 1 year of operation;

- spare parts kit;

- locksmith tools for machine maintenance;

- installation shoes-4 pcs.;

- set of operational documentation: (operating manual for the machine; operating manual for electrical equipment; spare parts catalog; management instructions – 1 copy).

Mandrel for the grinding wheel static balancing,

Device for the grinding wheel static balancing,

Centrifugal coolant cleaning station-centrifuge.

Exhaust device "UV-1200.00.0.000.0.00". The device is designed to extract coolant mist with inclusions of solid dust and small metal shavings.

Cabinet protection.

Reverse centers.

Set of clamps.

Device for dressing the wheel at an angle.

Device for dressing the wheel on radius