- Index

- Catalog

- SURFACE-PROFILE GRINDING MACHINES

- SURFACE & PROFILE GRINDING MACHINE WITH CNC ORSHA-60150

SURFACE & PROFILE GRINDING MACHINE WITH CNC ORSHA-60150

DESCRIPTION

Machine is designed for high precision processing by the method of grinding flat and profile surfaces under conditions single-piece, small branch and serial production in all branches of industry connected with metal working.

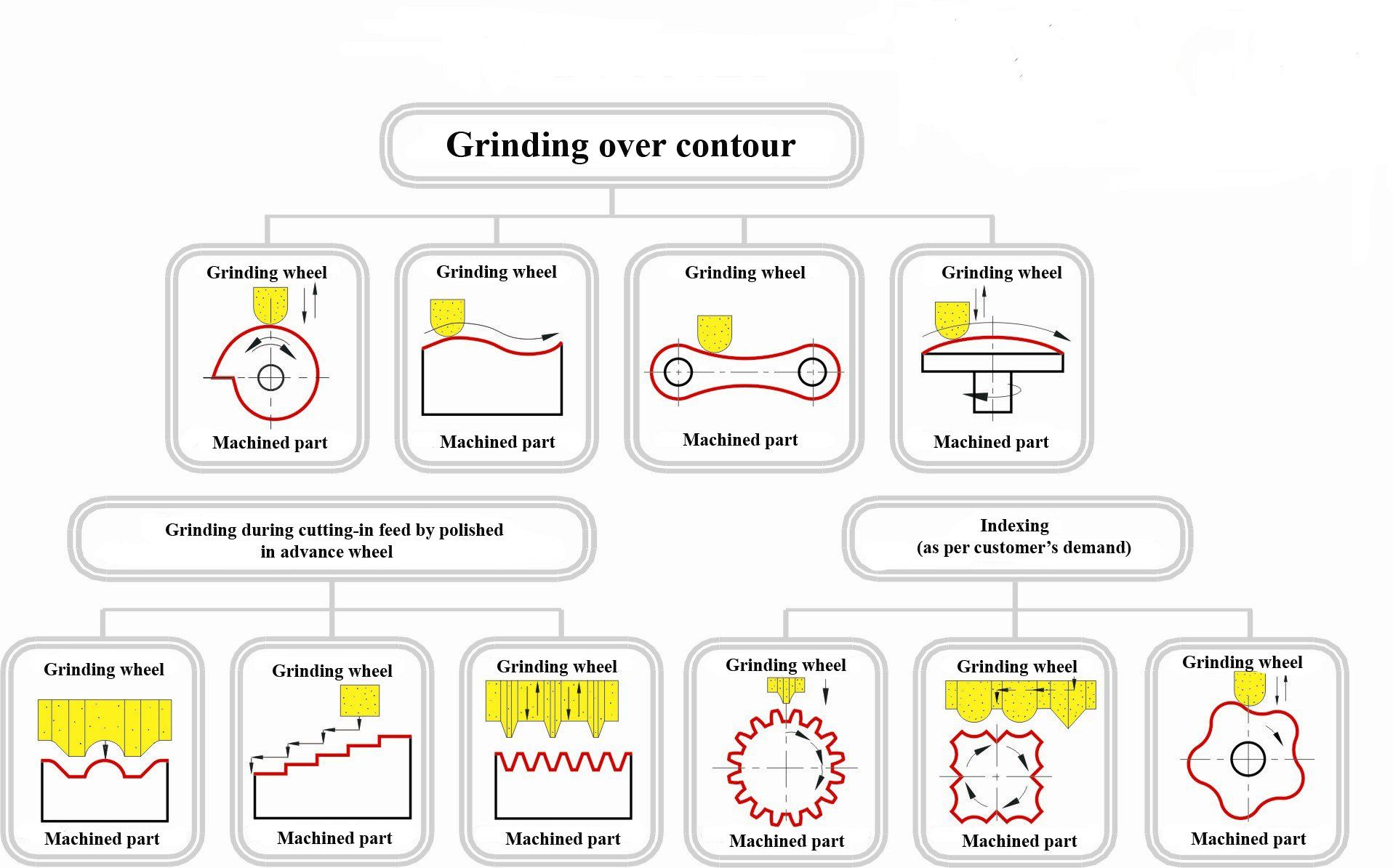

Grinding wheel dressing attachment with possibility of grinding wheel profiling over set profile is used which allows to machine profile surfaces. Grinding wheel profiling is realized by rotating diamond rollers installed on table by reciprocal displacement of wheel head and column over coordinates Y and Z.

Kinematic diagram of machine provides the following motions:

- grinding wheel rotation;

- vertical travel of wheel head (axis Y);

- cross travel of column (axis Z);

- longitudinal travel of table (axis X);

- of dressing mechanism installed on machine table from initial position into working one and then again back to initial position;

- rotation of dressing mechanism diamond rollers.

DESIGN ADVANTAGES

- Components of leading world producers

- Rigid structure of bed, column which are made from iron castings

- Super precise bearings of the firm IBC (in front support - 4 pcs., in rear support - 2 pcs.) are used in the grinding spindle supports

- Grinding wheel dressing mechanism with rotating diamond rollers which is installed on the machine table from the right

- Automatic lubrication of all guide ways of travels from the separate lubrication station

- Machine is equipped with cooling system. Tank capacity is 250 l, pump with productivity of 100 l/ min. There is a magnetic separator and paper filter conveyor for coolant treatment

- Feedback of control of travels over axes Y, Z is realized by photo pulse converters

- There is an electronic fly wheel for travel over coordinates Y and Z with discreteness 1 mkm

- Machine is equipped with system of digital program control CNC Sinumeric 828D of the firm “Siemens” with servo drives over coordinates Y and Z providing circular and linear interpolation

- Travel of all bodies are realized automatically (over axis X – from hydraulic cylinder, over plain slideways with durable polymer coating ; over axes Y and Z – by rolling ball screw pair, over hardened roller linear guide ways)

- Technical specifications

- Design description

- Delivery set

- Options

- Video

- Reference-list

- Reviews

-

Machine accuracy class

High

-

Table mirror width

600 mm

-

Table mirror length

1600 mm

-

Dimension of item sample

710 x 300 x 200 mm

-

Flatness

6 mkm

-

Parallelism

8 mkm

-

Roughness of surface machined by wheel periphery, Ra

0,32 Ra

-

Maximum mass of installed work piece (together with attachment and electromagnetic chuck)

1200 kg

-

Maximum distance between table mirror and spindle axis

640(790) mm

-

Grinding wheel diameter

400 mm

-

Grinding wheel height

20...100 mm

-

Grinding wheel bore diameter

127 mm

-

Main drive power

11,0 kW

-

Grinding spindle rotation frequency

1450 rpm

-

Maximum length of machined surface

1500 mm

-

Maximum width of machined surface with grinding wheel run-out (at wheel height 40 mm)

600 mm

-

Maximum width of machined surface without grinding wheel run-out

700 mm

-

Maximum height of machined surface

400(590) mm

-

Limits of table longitudinal travel (axis X)

2...28 mm/min

-

Wheal head vertical travel limits (axis Z)

0,001...0,3 mm/stroke

-

Cross travel limits (axis Y)

0,3...20 mm/stroke

-

Controllable number of coordinates

3

-

Discreteness of vertical and cross feeds

1 mkm

-

Overall dimensions (length x width x height)

5720 x 3850 x 2400 mm

-

Mass

9100 kg

The machine base is the bed on which compound slide, column, control panel, cross and vertical feeds mechanism are installed.

Machine compound slide provides longitudinal and cross table travel.

Column ensures vertical travel of wheel head.

All working travels on machine are automated.

Longitudinal table travel is realized by hydraulic cylinder.

Automatic and rapid travel of compound slide is realized through the belt transmission from induction electric motor.

Automatic vertical feed is realized from hydraulic motor through reducer and rapid travel is from induction electric motor through the belt transmission and reducer.

Manual travel of compound slide, wheel head and table is executed by hand wheels.

Spindle rotation is realized by induction electric motor.

Machine hydraulic station is fulfilled as a separate unit and installed to the right from the machine.

Machine control panel is located on the bracket which is fastened to the bed. Cooling system unit is installed from the left side of machine.

COLUMN

Column is mounted on the rear wall of the bed and serves for realization of vertical travels of wheel head which is installed and rigidly fastened on its top surface.

Guide ways of surface are formed by column itself and the bars screwed onto the bed. Preload in system of vertical guide ways is achieved :

-in the plane parallel to the grinding spindle axis - by means of rigid bushings and force of disk springs;

-in the plane perpendicular to the grinding spindle axis – at the expense of guide ways of V-shaped form use.

Vertical travels worm-and-wheel gearbox is fastened to the lower plane of the column.

LEFT CROSS GUIDE WAY

Left linear slide roller bearing has U-shaped form in section, perceives vertical and side loads. For ensuring high rigidity and accuracy of cross travel of compound slide U-shaped guide way is assembled with preload which is created with wedge by means of the screw, then the wedge is fixed by the screws.

COMPOUND SLIDE

Compound slide ensures cross and longitudinal travel of table. Longitudinal linear bearings (V-shaped and flat ones) over which the table travels, is located on top plane of compound slide. Hydraulic cylinder of table drive is rigidly fastened between longitudinal guide ways.

Bracket which is connected with the nut of ball-screw pair of cross feed mechanism is fastened to the lower surface of compound slide. The sliding bar over which table reverse cams travel is installed on the front wall of compound slide, under guard board. Tabs interacting with contactless switches located on table are installed on cams. Position of cams is adjusted depending on the length of machined part. Mechanism of table manual travel is fastened from the front, to the left on compound slide.

TABLE

Table has working surface with three Т-shaped slots for installation and fixation of machined parts, electromagnetic chuck or setting fixture. On lower plane of table the longitudinal slideway bearings - V-shaped and flat ones are located and also toothed rack which provides the manual travel of table from the gear of manual travels mechanism . Brackets are stiffened over edges of lower table surface. Rods of hydraulic cylinder are connected to those brackets. Protection of working zone is installed on top plane of the table.

Collection of coolant takes place in the table bath, and discharge – through aperture in the rear wall of table into collector and further on to cooling tank.

CROSS FEED MECHANISM

Cross feed mechanism provides:

-manual travel of compound slide;

-automatic feed;

-rapid travels;

-hand wheel switching off by electromagnetic clutch during automatic travels of compound slide.

WHEEL HEAD

Wheel head consists of body and spindle. Spindle is installed on high precision radial-thrust bearings assembled with preload.

Supporting thread end of rolling ball-screw pair of vertical travels is fastened rigidly to the lower surface of wheel head body.

Special canals and labyrinths are made in flange with the purpose of providing the protection of leading foot bearings.

VERTICAL FEED MECHANISM

Vertical feed mechanism provides:

- automatic vertical feed;

- manual rough or fine travel of wheel head;

- hand wheel switching off by electromagnetic clutch during automatic travels of wheel head.

COOLING

Cooling consists of welded tank on which electric pump for coolant and magnetic separator for coolant treatment from metal slime are installed. Slime is collected in a separate tank.

Emulsion discharge from the table takes place through collector fastened on compound slide into the tray installed into magnetic separator.

HYDRAULIC CYLINDER

Hydraulic cylinder is installed on top surface of compound slide and realizes reciprocal motion of table. Hydraulic cylinder rods are fastened by nuts to table brackets. Rods are sealed by rubber glands. Table braking by means of special cones is foreseen in the extreme positions of piston stroke.

HYDRAULIC DRIVE STATION

Hydraulic drive station is designed for providing reciprocal travel of table with adjustable speed, output of table into loading zone, vertical feed mechanism drive and realization of centralized automatic lubrication of guide ways.

Station works on clean mineral oils with kinematic viscosity from 30 to 35 mm2/с (r/St) at temperature 40°C designed for hydraulic systems with antioxidant and wear-preventive additives.

Recommended trademarks of oils: ИГЛ-18 ТУ 38.101413-78, ИГП-30 ТУ 38.10141З-78.

LUBRICATION SYSTEM

Lubrication system is designed for centralized lubrication of all guide ways from hydraulic system. It is switched on automatically when machine hydraulic drive is switched on.

Oil enters the lubrication system from hydraulic drive station through filter with filtration accuracy of 25 mkm. Drainage of lubrication is discharged into a sediment box designed for oil cleaning before discharge into hydraulic station. Sediment box is equipped with a magnetic separator.

Delivery set of machine includes:

- cooling system with magnetic separator;

- table drive hydraulic station;

- lubrication hydraulic station;

- electric automation cabinet;

- control panel;

- grinding wheel dressing by diamond rollers mechanism;

- set of spare parts and attachments, quick wearing parts and tools;

- attachment for static balancing of grinding wheel with arbour;

- in-line documentation set;

- mounting pads for machine installation on foundation;

- electronic fly wheel for traveling over coordinates;

- electromagnetic chuck: 600x1200 mm (ORSHA-60120) – 1pc.

600x800 mm (ORSHA-60150) – 2 pcs.

600x1000 mm (ORSHA-60200) – 2 pcs.

600x1200 mm (ORSHA-60240) – 2 pcs.

600x1000 mm (ORSHA-60200) – 3 pcs.

Cabinet enclosure of working zone of machining. Enclosure of machine is a welded frame installed on bed and is designed for protection against coolant-lubricant spraying during work.Cabinet type enclosure is a frame with closed top and movable sliding door.

Installation of ball-screw pair with corresponding servo drive on table drive (axis X) instead of hydraulic cylinder

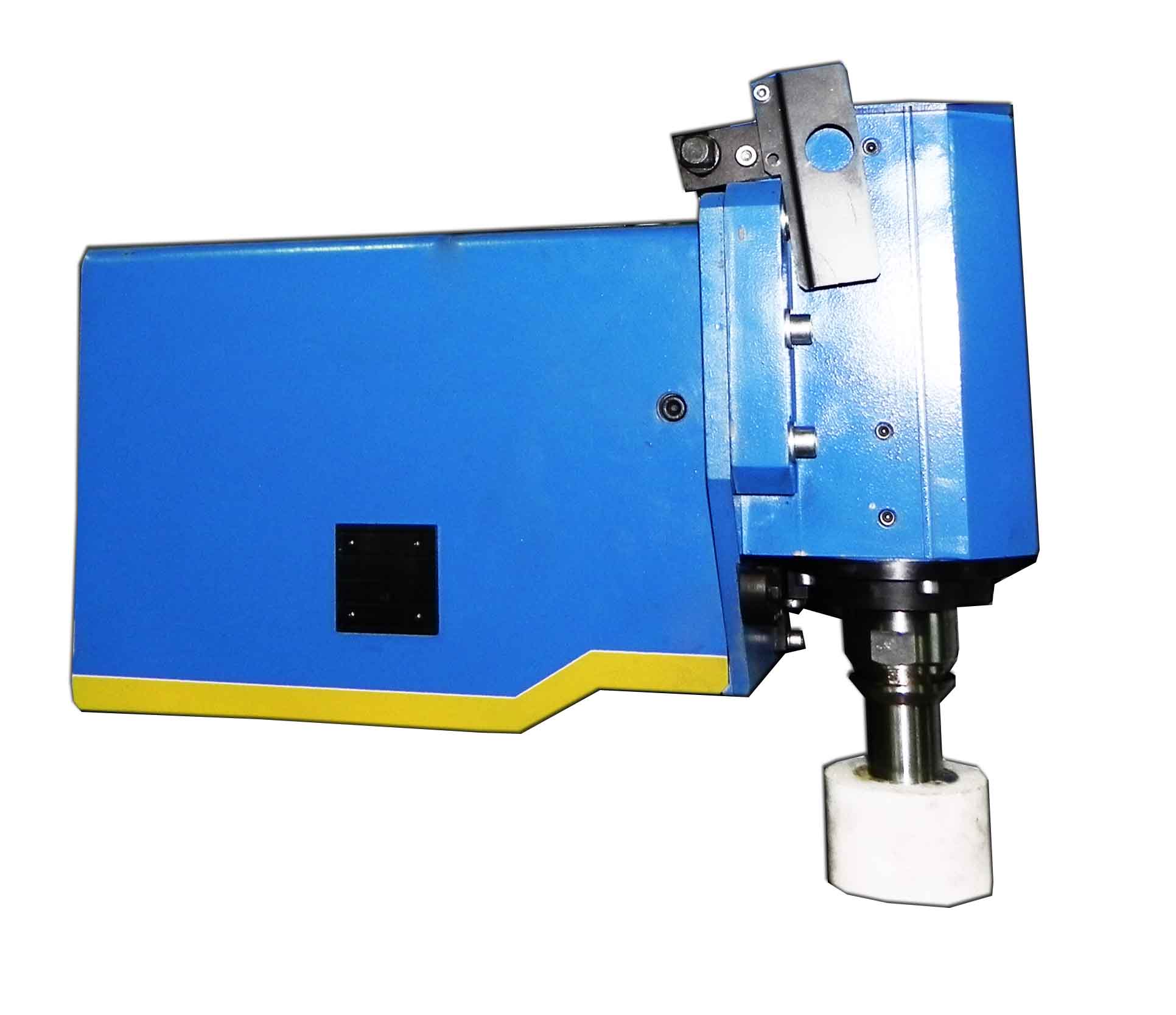

Equipping of machine with grinding wheel dressing mechanism over periphery by dresser diamond which is mounted on wheel head instead of profile dressing mechanism on table

Equipping the wheel head with grinding wheel dynamic balancing device. This option includes balancing head of flange type with contactless transmitter, vibration sensor and electronic device. Use of this device allows to produce automatic balancing of rotating grinding wheel on machine with minimum imbalance.

Equipping with device of part position control. This option includes mechanism consisting of bracket on which axis with lever is fastened. Touch sensor with probe is fastened in the lever. Lever turns on the axis by linear pneumatic cylinder. Touching the machined part is produced by means of touch sensor of the firm “Renishaw” and its linear coordinates are determined which afterwards are used in the control program (CP) of machining

Ball screw transmission (rolling screw-nut) onto table longitudinal travel. This option includes rolling screw-nut transmission, installed between top guide ways of bed. Transmission serves for table travel. Rotation of feed screw is realized by pulleys of belt gear transmission from electric motor Siemens installed on plate from the right side of the bed.

System of coolant feed and treatment with magnetic separator and filter –conveyor. This option includes tank with pump for coolant-lubricant feed into the zone of machining and filter –conveyor with roller filtering cloth and also magnetic separator which is installed on the frame of filter-conveyor. Filtration of coolant-lubricant takes place at first through magnetic separator, then through filter-conveyor. Capacity of magnetic separator is 50 l/min, of filter-conveyor is 100 l/min.

Manufacturing the machine with master controller and manual control is possible